Summary of molds

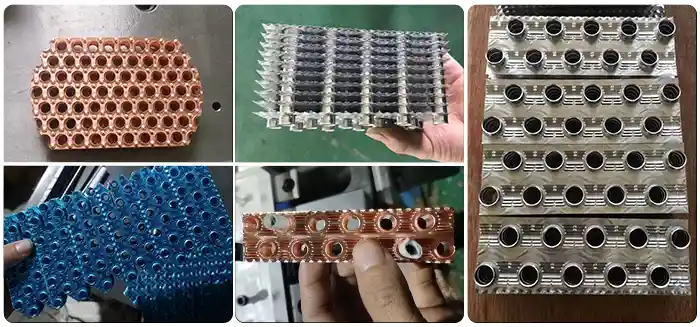

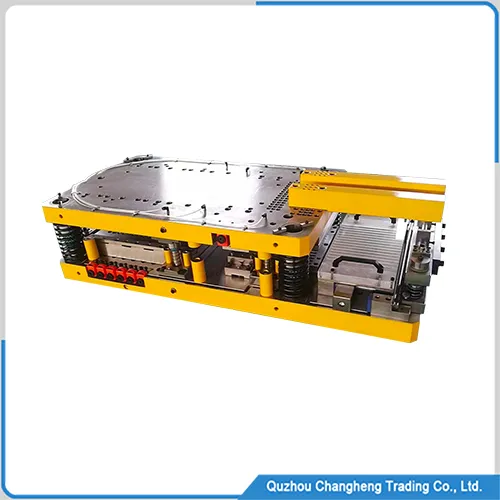

This is a fin press die for the HVAC refrigeration industry. It is a mold that combines multiple stamping molds with different functions to achieve high-speed automated production. It has a mechanical structure moving device that can accurately move materials during high-speed production by pressing 280 times per minute

As is well known, stamping molds can cause wear and tear on parts during long-term production. To solve this problem, our mold’s key components are design independently. When there is slight wear and tear, it can be replaced at a very low cost, extending the service life of the entire mold

With the continuous development of industry, this fully automatic mold has been increasingly favored by more and more people. It can not only improve production efficiency and maintain high product size consistency, but also significantly reduce labor costs

Fin press die data

| No. | ITEM | DATA |

| 1 | hole rows | based on geometry |

| 2 | Foil thickness | 0.05-0.5mm |

| 3 | Materials | aluminum copper Stainless Steel |

| 4 | Enhancements | Louwered – Lance |

| 5 | Collar height | 1.5-12mm |

| 6 | Fin Edge | Plane Corrugated |

| 7 | Fin length | freely controlled |

| 8 | hole diameter | customized |

Advantage of fin press die

- High production efficiency

This mold adopts a continuous automation production method, with built-in functions such as stretching, forming, cutting, and moving. Its fastest production speed can reach 280 times/minute, and the production efficiency is very high, which is very suitable for factories that need large-scale production.

- High precision manufacturing technology

Almost all mold parts are CNC machining high-precision manufacture, and some parts require grinding treatment with high surface smoothness requirements to ensure that the dimensions of the produced parts meet customer requirements.

- Save raw materials

The layout of this fin press die has been scientifically design and comes with built-in cutting blades. Users can produce fins of different widths according to the size of the heat exchanger. Moreover, there will be no material waste during the production process.

- Reduce labor intensity

The fin pressing mold does not require worker participation in the production process, which not only reduces labor participation, but also lowers the labor cost of the factory, bringing more possibilities for the sustainable development of the factory.

Fin press die Manufacturer factory video

Other types of stamping mold

Plastic Injection mold for radiators

Product Overview This plastic injection mold is a special tool for the production of radiator tanks. Its internal cavity is designed according to the characteristics of automobile radiators. When the material is injected into the…

Sawtooth fin mold of plate and fin heat exchanger

Product Description The dedicated tool for the entire sawtooth fin mold plate and fin heat exchanger is made of high-hardness steel, and the key serrated parts are vacuum quenched to ensure their hardness and wear…

Fin progressive die of heat exchanger

Fin mold summarize This type of fin progressive die is a key component in the field of heat exchangers, consisting of multiple independent pressing units to produce a complete fin part in one press, thereby…

Continuous fin mold and Progressive die

Condenser fin mold Continuous fin mold, also known as fin progressive die, is a die that is divided into several equidistant stations according to the workpiece being processed, One or several basic stamping processes are…

Structure and design of fin press die

It consists of two large templates, multiple independent small molds, and guide columns. Each small mold completes different functions, such as stretching, punching, cutting, etc., and then realizes the automation production of this mold

Designing this kind of mold is a test of the designer’s ability. He should not only be proficient in stamping technology, but also have a deep understanding of materials and mechanics. Not only that, he should also have enough experience in the production process of fin. If the production process is not scientifically distributed, it may directly affect the production efficiency and product quality

With the popularization of industrial design software, mold design engineers will use design software for simulation analysis, optimize design before mold manufacturing, and avoid potential risks. This not only improves work efficiency, but also reduces manufacturing costs

WHY CHOOSE US

- The key parts of the fin pressing die have undergone vacuum heat treatment, which has extended the service life of the die. We guarantee that the die does not need to be repaired after 400 million times of pressing

- Our engineers have an average of 15 years of work experience, and their rich experience can be uses to design various automated molds,

- No matter your raw materials of fin are iron, stainless steel, copper, aluminum, etc., we can provide you with perfect solutions, and our price has absolute advantages

- Our factory has a complete set of production machinery, CNC machining all mold parts, which can meet strict tolerance requirements

WECHAT

WECHAT