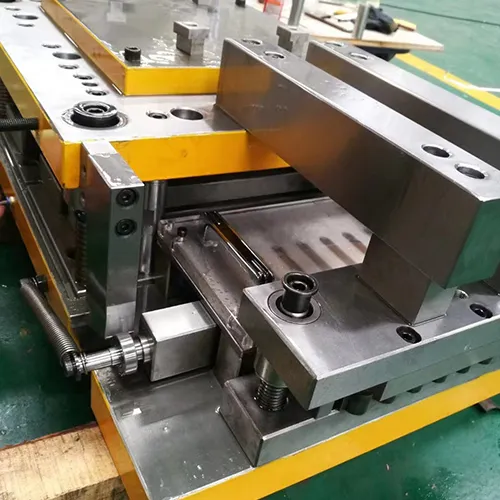

Fin mold summarize

This type of fin progressive die is a key component in the field of heat exchangers, consisting of multiple independent pressing units to produce a complete fin part in one press, thereby achieving high-speed production

All parts of this progressive die are manufactured using high-precision machines. A single die can guarantee 20 million stamping times, and the blade can be repaired 10 times. The total service life of the mold is 8-10 years.

Another advantage of it is the ability to flexibly exchange mold tools, enabling the production of various fins of different sizes to meet the needs of different types of heat exchangers,

Fin progressive die advantage

1, This mold is suitable for industrial fields such as automotive radiators, household air conditioners, central air conditioners, dehumidifiers, etc.

2, With over 15 years of professional experience in designing this type of fin progressive die, we can easily meet your requirements regardless of whether your fin hole shape is circular, elliptical, or waist-round

3, All steel is manufactured in Japan or Sweden, and the blade material is asp30 or hap40. This steel material can meet long-term high-speed production with almost no wear and tear

4, The structural design of this mold is reasonable and easy to maintain. All parts are precision machined, and some standard parts (including guide pillars, guide sleeves, springs, screws, etc.) are from famous Chinese brands

Fin die details

| ITEM | DATA |

| mold name | progressive die |

| OD | 9.52mm |

| Number of columns | 12 rows |

| Flanging height | 1.8mm (0-0.1mm) |

| Quantity | 1 set |

| Fin material | aluminum foil |

| foil | 0.12-0.15mm |

| stamping speed | 120-250/min |

Fin Progressive die manufacture video

FAQ

A: The maximum collar height is 8mm. If you need a higher size, please contact our engineer for more details.

A: Of course, the largest mold we manufacture is 25 rows, and we can manufacture larger sizes if you need greater.

A: The normal delivery time is 45 days, and the delivery time for customized molds is 60-65 days.

WECHAT

WECHAT