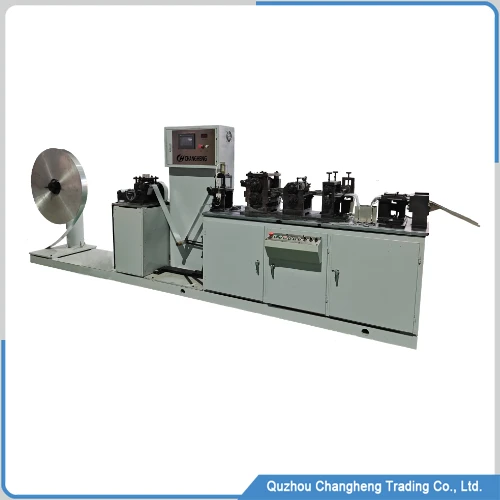

Condenser fin mold

Continuous fin mold, also known as fin progressive die, is a die that is divided into several equidistant stations according to the workpiece being processed,

One or several basic stamping processes are set at each station to complete the processing of a part of the stamping workpiece.

The material to be processed shall be processed into strips of a certain width in advance, and a certain feeding method shall be adopted to feed one step at a time.

After punching one by one, a complete stamping workpiece is obtained.

In the ten pairs of progressive dies, blanking, bending, drawing, forming and other processes can be completed continuously.

No matter how complex the shape of the stamping part is and how many stamping processes are, it can be completed by stamping with a pair of Continuous fin mold and fin progressive dies.

Continuous fin mold Technical parameters

| No. | item | data |

| 1 | Hole diameter | 9.53mm(3/8’’) |

| 2 | line number | 4-12 rows |

| 3 | Hole array | 25*22mm |

| 4 | Fin width | 248mm |

| 5 | Overall size | 1050*240*220mm |

| 6 | Production type | automatic |

Raw materials of Continuous fin mold

- The big mold plate is EN C45,

- The small mold plate is Cr12MoV,

- The punching needle is SKH51,

- Louver parts is SKH51,

- Spring is 50CrVA,

continuous die manufacture factory video

FAQ

A: Yes, each of our progressive die is customized according to customer requirements

A: Our progressive die delivery time is 55-65 days

A: Our Continuous fin mold are packed in wooden cases

A: Our dies are suitable for more than 90% of stamping machines, You can contact our engineer and provide pictures of your stamping machine

WECHAT

WECHAT