Machine Overview

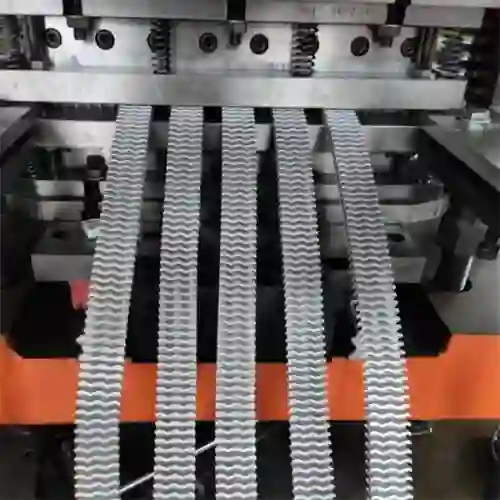

The fin press line is precision equipment specifically used for manufacturing heat transfer fins, which are key components in heat exchangers that enhance heat exchange efficiency.

Heat exchangers are widely uses in various industries, including—but not limited to—automobiles, ships, air conditioning and refrigeration systems, hydraulic oil cooling, and other fields.

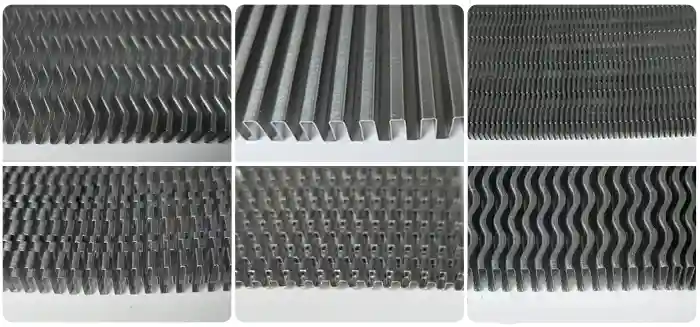

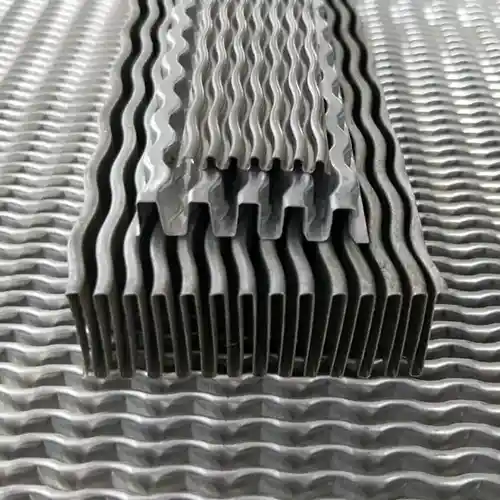

This Fin press line has a high-precision mold and control system, which can produce fins of different shapes.

Automated fin-forming machines can improve production speed, reduce manual errors, and ensure product quality and consistency.

The material types that this Fin press line can process (such as aluminum, copper, or other alloys),

can produce different geometric shapes of fins (such as straight fins, corrugated fins, etc.), with low-cost mold replacement,

Low-cost equipment investment generates maximum benefits, which is crucial for heat exchanger manufacturers

Fin press line data

| No. | ITEM | DATA |

| 1 | Fin spacing | 1-15mm optional |

| 2 | Fin length | Any length |

| 3 | Fin height | 1.5-12mm |

| 4 | Machine noise | 60 decibels |

| 5 | External dimensions | 140*100*165cm |

| 6 | Energy consumption | 5.5kw |

| 7 | Power supply | 3-phase, 380V |

| 8 | Max working size | 300mm 450mm optional |

| 9 | Metal materials | aluminum copper Stainless steel titanium |

Fin press line advantage

1, It features a robust 4-column design, which ensures stability during operation, and is equipped with an automatic lubrication system to maintain optimal performance and reduce maintenance requirements.

2, The components of the control system are from international brands Siemens and Mitsubishi

3, The Fin press line is capable of full-automatic production, enhancing productivity and minimizing the need for manual intervention.

4. It utilizes servo motor drive technology to control the length of the fins accurately, ensuring consistent quality in the finished products.

5, This machine can achieve low-cost mold replacement and produce various types of fins, such as wavy, serrated, linear, etc., thereby increasing the flexibility to meet different production needs.

6. the machine can also process different raw metal materials, such as aluminum, stainless steel, titanium alloy, copper, etc., providing versatility to adapt to different applications and requirements.

Fin press line manufacturer factory video

Fin type

Installation precautions

1. The installation of this machine requires putting the cutting equipment, fin machine, and feeder in line.

2. Connected to a power source If the factory floor is uneven, you can adjust the foot screws of the machine to keep it stable.

3. The machine’s sheet metal parts have been welded by a butt welding machine, which is sturdy and durable. However, during the machine’s installation process, no objects are allowed to hit it.

A cylinder drives the cutting device, so it must connect to compressed air at 0.4-0.6mpa to operate normally.

4. The mandatory requirement for ship transportation is that no oil is ratifying inside the machine, so when installing the machine, you need to add 38 # engine oil.

WECHAT

WECHAT