Machine Description

As advanced production equipment, aluminum fin machine play an important role in improving production efficiency and reducing costs for factories in the field of automotive radiators.

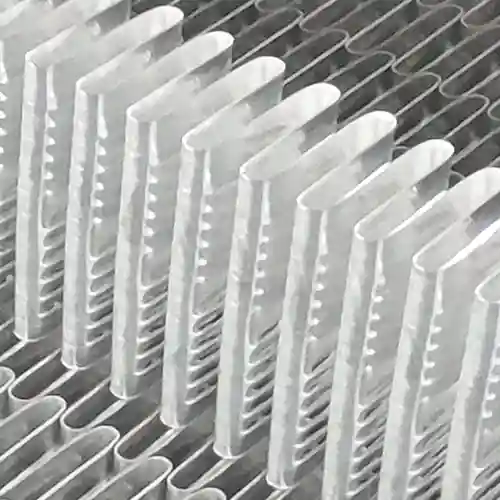

It is mainly used to produce corrugated aluminum fins with a fin height of 8mm, providing a reliable solution for various automotive and truck, engineering vehicle radiator, and condenser applications.

The core component of the aluminum fin machine is the roller forming device, which is a blade made of metal with high tungsten content.

After precise mechanical cutting and grinding, it is combined into a roller mold. This device is independently designed and can easily replace molds of different sizes to meet different production needs

The control system of this aluminum fin machine integrates PLC, frequency converter, servo motor drive control, and touch screen control. The machine can be precisely controlled during the production process, ensuring that the size, shape, appearance,

and other requirements of each fin meet high standards.

Operators can easily set and adjust various parameters, such as fin height, production speed, etc., through the touch screen. The user-friendly design of the touchscreen makes operation more convenient and greatly improves production efficiency.

Aluminum fin machine data

| No. | ITEM | DATA |

| 1 | Voltage | 3.5kw |

| 2 | Lubrication | including |

| 3 | Aluminum foil thickness | 0.05-0.12mm |

| 4 | Minimum order quantity | 1 pcs |

| 5 | Aluminum fin width | 1-180mm |

| 6 | Fin material | copper aluminum |

| 7 | Production speed | 100 meters |

application area

- auto radiator

- Truck intercooler

- Engineering vehicle oil cooler

- Generator radiator

- Diesel engine cooler

- Household air conditioning condenser

- Automotive Condensers

- Vehicle air conditioning heater

- Computer cooling

aluminum fin machine video

summarize

Aluminum finned machines, with their efficient and precise production capacity and advanced technological configuration, have become a must-have equipment for many radiator and condenser manufacturers.

Aluminum finned machines play a crucial role in household air conditioners, industrial heat exchangers, and automotive radiators. Its widespread application undoubtedly brings enormous economic and social benefits to modern industrial production.

FAQ

A: The control system of this machine is controlled by PLC and touch screen, and the touch screen language is English and Chinese.

A: Yes, it can not only produce fins for truck radiators but also fins for various heat exchange parts such as condensers, evaporators, heaters, etc.

A: This machine requires lubricating oil during high-speed production. This equipment is already equipped with an automatic lubrication device, and you only need to add volatile oil.

WECHAT

WECHAT