Machine outline

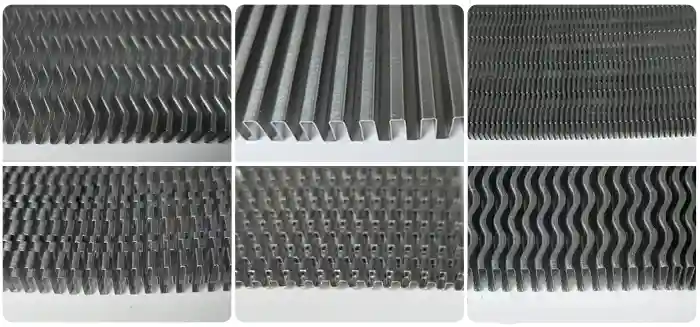

The industrial cooling system oil cooler fin making machine, as the core equipment for processing industrial cooling systems such as radiators, condensers, intercoolers, oil coolers, and heat exchangers, has become an important specialized processing equipment in this field.

With its advantages such as reasonable structural design and efficient production, this fin-making machine is widely used in industries such as automobiles, ships, air conditioning, compressors, engineering machinery, mining machinery, aviation, military, and hydraulic oil cooling.

After continuous updates and optimization design, the fin-making machine can currently produce cooling fins of different materials, such as aluminum, copper, iron, stainless steel, titanium alloy, and other raw materials, to meet the market needs of different customers

Fin making machine advantages

1, Stepless regulation: The production speed of this equipment can achieve stepless regulation, breaking the limitation of traditional mechanical speed regulation with few gears.

2, Compact structure: We have comprehensively optimized the machine’s structure to make it more reasonable and convenient for workers to operate.

3, Stable performance: With the improvement of production accuracy, the long-term wear and tear during production is reduced, and compared to the previous generation of fin manufacturing machines, the performance is more stable

4, Easy maintenance: The equipment is already equipped with an automatic lubrication system, which can almost ignore maintenance costs during normal use

Quick Details

| No. | ITEM | DATA |

| 1 | Feeding speed | 120times / min |

| 2 | Fin materials | iron aluminum stainless steel titanium alloy copper |

| 3 | fin height | 1.5-12mm |

| 4 | max fin width | 300/450mm |

| 5 | aluminum foil | 0.04-0.5mm |

| 6 | Total power | 7.5kw |

| 7 | air source pressure | 0.6MPa |

| 8 | Total weight | 1.8 tons |

Fin making machine working video

FAQ

A: The delivery time of this machine is 55 days.

A: This machine is packed in wooden cases.

A: Yes. This machine can produce fins of any shape by changing the mold.

A: This machine is a PLC control system.

WECHAT

WECHAT