Machine Overview

There are many types of fin tube making machines, which are applied in different fields. This article covers almost all types of fin tube production equipment in the current industrial field

Whether you are looking for low-finned tube machines or bimetallic finned tube machines, we can provide you with a one-stop solution to meet your needs here

More finned tube machines

Spiral tube machine From Chinese suppliers

Machine Overview The Spiral tube machine is a production equipment for squeezing metal pipes. The machine squeezes the pipes to form a spiral shape inside,…

Low fin Machine Manufacturer in China

Machine Overview The Low fin machine is an industrial production equipment that has three sets of rollers to squeeze metal tubes, forming a spiral-shaped low…

Extruded fin tube machine

Machine Overview The extruded fin tube machine adopts roller extrusion, which is currently the most efficient metal tube forming process in production. The device is…

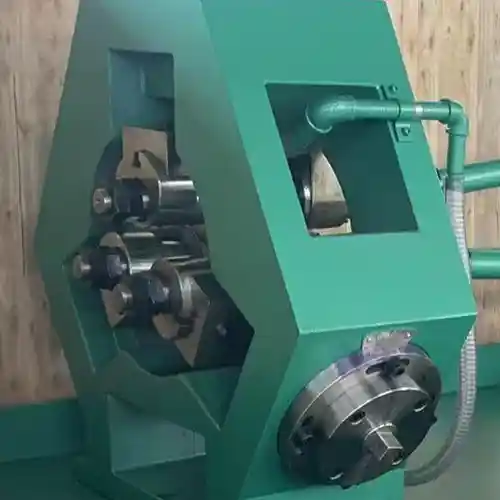

Fin tube rolling machine

Machine Overview The fin tube rolling machine adopts a design of three sets of symmetrically arranged rollers, which are driven by a single motor to…

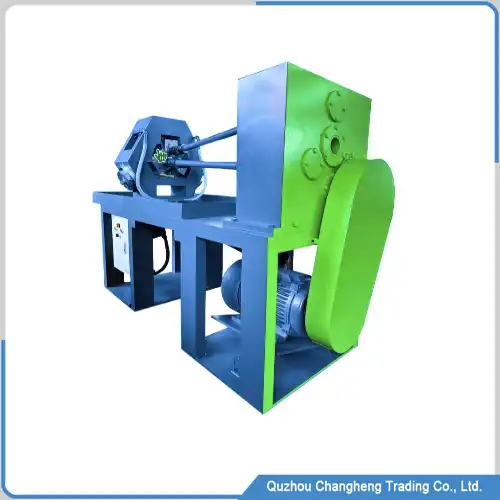

Extruded Finning Machine

Machine Overview The Extruded Finning Machine adopts a 3-roller extrusion technology to produce finned tubes, which can ensure strong bonding between fins and tubes and…

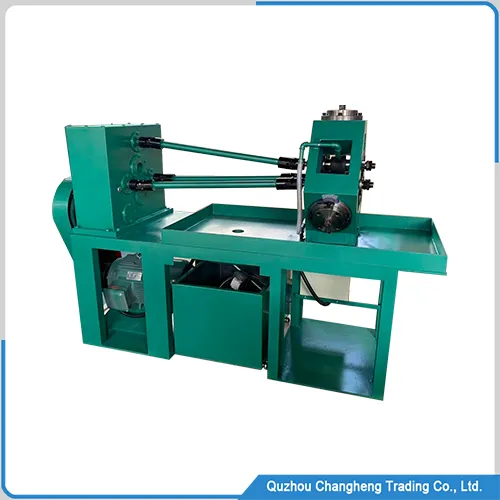

Tube Fin Machine Supplier in China

Machine Overview The tube fin machine is an important industry equipment. It adopts an advanced three-set rolling roller design, and the uniform pitch of the…

fin tube winding machine

Machine Overview The fin tube winding machine is a device used for manufacturing heat exchanger fins, which uses a 5.5 kW motor as the main…

Finning Tube Machine Manufacturer

Machine Outline This Finning Tube Machine is used to produce circular fin tubes, with a reasonable structural design, strong extrusion ability, and simple control, which…

Fin tube machine working video

technical parameter

| No. | ITEM | DATA |

| 1 | Workbench height | 720mm |

| 2 | Output speed | 120 rpm |

| 3 | Min tube diameter | ± 15mm |

| 4 | Fin outer diameter | 18-70mm |

| 5 | Shaft diameter | 45mm |

| 6 | Fin pitch | 0-8.00mm optional |

| 7 | Tube length | 0-15000mm |

| 8 | Main motor power | 11KW |

| 9 | Cooling | liquid cooling |

| 10 | Machine weight | 1500kg |

| 11 | External dimensions | 220*76*145cm |

How to choose the appropriate machine

Choosing the right machine is crucial for producing fin tubes, and selecting the right fin tube machine requires considering the following key factors:

1, Material of fins

Producing different fin materials, fin tube equipments have some differences, such as producing copper fin tubes, which require high-power motor drive

2, The production process of fins

At present, there are different production processes for fin tubes applied in the industrial field, including aluminum foil winding type, aluminum tube extrusion type, and single metal rolling type. It is necessary to choose the correct production process

3, Accuracy of the machine:

The production of finned tubes requires high precision, so it is necessary to choose a fin tube-making machine that can ensure high-precision processing to ensure product quality.

4, Speed and efficiency:

Consider the processing speed and overall production efficiency of the machine to ensure cost-effectiveness.

5, Price and budget:

Considering the cost-effectiveness of the machine while meeting technical requirements, select a model that meets the budget.

6, Technical support and services from suppliers:

Choose suppliers who can provide good technical support and after-sales service, so that they can receive timely help and guidance when encountering problems during use.

7, Safety performance:

Ensure that the machine complies with the safety regulations of laws and regulations to ensure the safety of operators. This is also a crucial element

WECHAT

WECHAT