Machine Overview

The tube fin machine is an important industry equipment. It adopts an advanced three-set rolling roller design, and the uniform pitch of the formed fins achieves precise and reliable displacement.

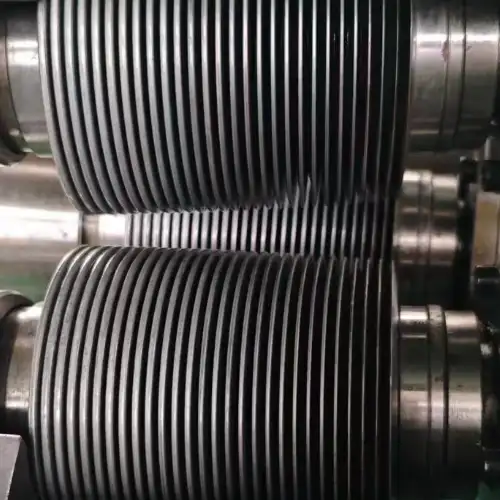

The three rollers are arranged in parallel triangular structures, each with high-quality bearings to make it roll more smoothly. The other end is connected to the gearbox with a universal joint to transmit power output.

The roller adopts a replaceable structural design, and different sizes of roller molds are replaced to achieve diversified production of fin tubes,

meeting the heat transfer efficiency requirements of varying heat exchangers.

Tube Fin Machine Key Advantages

Flexibility

By changing different roller molds, the shape and size of the fins can be easily change to meet different design and application requirements.

High precision

The rolling process is a safe and stable production process that can produce highly uniform fins. The fins’ forming and precision are achieved through precisely controlled roller molds.

Material strength

Compared with other cutting processes, pipe fin rolling does not weaken the wall thickness of the pipe and affect the material strength of the pipe,

Efficient production

The automatic cooling device and pipe fin machine are designed to be separated, ensuring the production speed is not disturbed. This structure is very suitable for large-scale production.

Tube fin machine data

| No. | ITEM | DATA |

| 1 | Fin material | Copper and aluminum |

| 2 | Roller mold | Replaceable |

| 3 | Inner tube material | Any metal |

| 4 | Fin pitch | According to design |

| 5 | Power supply | 380v |

| 6 | Motor | 11kw 22kw Optional |

| 7 | Blade cooling | Automatic |

| 8 | Machine color | Green |

| 9 | Delivery time | 26 days |

Tube fin machine roller mold

The Fin tube machines are state-of-the-art equipment design specifically for producing fin tubes. The mold plays a key role in the extrusion production process, and it is circular in design, with multiple rollers combined to form a complete mold.

This mold’s blade material is wear-resistant special steel. Each blade is making using high-precision technology. It has a unique size and performs well during the production process.

Replacing these molds requires strictly arranging them in their order, with each circular blade having an independent number. If done incorrectly, they will not function properly and may even cause the blade to break.

Why choose our tube fin machine

1. We offer the fastest delivery time of 25 days so that you can push the product to the market faster and meet urgent project deadlines.

2. The safety mechanism equipped in the structural design of the tube wing machine allows easy control of the machine with only two buttons, which can protect the operator during operation.

3. Low-cost rolling molds can produce finned tubes of various sizes, so you can flexibly adjust production according to different application needs without investing much money in mold replacement.

4. The intelligent drum cooling device is the key to high-speed production, which can prevent the drum blades of the tube wing machine from overheating, ensuring production efficiency and product quality.

5. A highly competitive price means obtaining high-performance equipment within a limited budget, optimizing your investment return.

Tube Fin machine working video

Tube fin machine advanced function

There are three sets of extrusion roller molds for this finning machine, each with an adjustable screw and a scale around it. Engineers can adjust this screw to produce fin tubes of different diameters,

This means that this set of molds can produce fin tubes of various diameters without the cost of any molds. The diameter range of the tubes is 9.52-70mm, which already meets 90% of the demand in the heat exchanger market.

This friendly design allows the fin roller mold to play its full role and saves users a lot of capital investment.

Summarize

If you are looking for this type of finned tube machine to produce heat exchangers, then our machine should be one of your best choices,

It not only has high-precision mold design but also control methods for safety measures, independent coolant devices, etc., providing great assistance for your efficient production

Contact our engineers for more equipment details and start your project

WECHAT

WECHAT