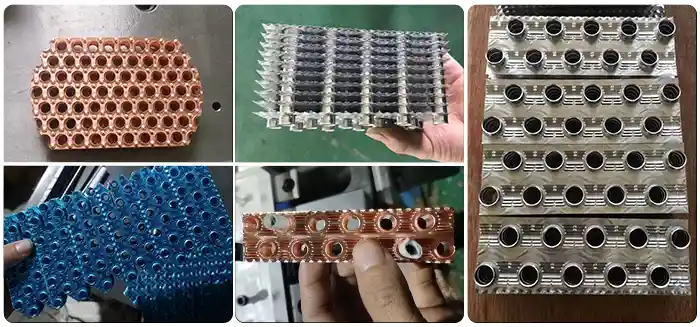

Press Die Overview

As a leader in the field of designing and manufacturing fin press die, we are dedicated to providing customized solutions to meet your unique foil fin needs. Our mold design can quickly change molds, ensuring that the production process is both flexible and accurate.

The fin press die we manufacture always maintains a high degree of uniformity and can operate stably under strict process conditions, meeting the precision requirements of complex fin designs.

Whether it is the high-quality fins produced in each compression cycle or the high-quality products produced over the long term, we have proven our leading position in the industry.

Fin press die data

| No. | ITEM | DATA |

| 1 | hole rows | based on geometry |

| 2 | Foil thickness | 0.05-0.5mm |

| 3 | Materials | aluminum copper Stainless Steel |

| 4 | Enhancements | Louwered – Lance |

| 5 | Collar height | 1.5-12mm |

| 6 | Fin Edge | Plane Corrugated |

| 7 | Fin length | freely controlled |

| 8 | hole diameter | customized |

Advantage of fin mold

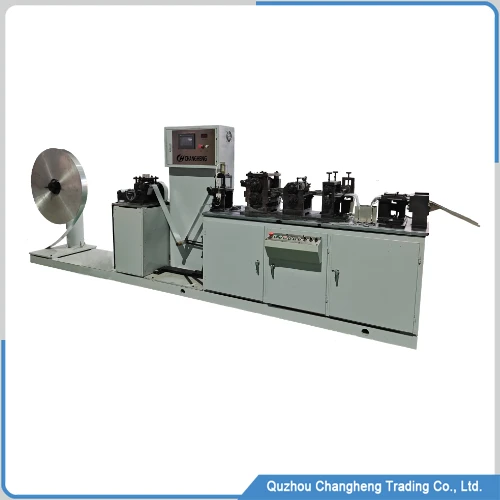

1, High production efficiency:

The fin progressive die adopts a continuous automatic production method, which can be pressed 280 times per minute, resulting in high production efficiency

2, High precision:

Because all parts of the mold are processed by CNC machine tools, the precision and shape accuracy of all dimensions of the fins can be guaranteed.

3, Material saving:

During the production process of the fin press die for fins, the material utilization rate is high and there is almost no waste of raw materials

4, Reduce labor intensity:

The production process of fin progressive molds is automated, and the entire production process does not require manual intervention

5, Suitable for large-scale production:

Fin press dies are suitable for large-scale production and can reduce production costs.

WHY CHOOSE US

With the continuous advancement of technology and the growing demand for energy conservation, the shape of fins has become increasingly diverse, and tolerances have become stricter.

We have chosen an integrated mold design scheme, and the entire mold plate will be processed through one-time CNC machining to meet strict tolerance requirements

Reasonable structural design has increased heat transfer efficiency by 12%.

The fin mold adopts multiple distributed stretching designs and can produce a maximum collar height of 15mm

The key components of the mold are all treated using heat treatment technology, and the entire service life of the mold exceeds 400 million presses.

WECHAT

WECHAT