Machine Overview

This radiator fin machine is an advanced production equipment widely used in fields such as automobiles, trucks, and engineering vehicles. This equipment efficiently produces high-quality radiators, condensers, and heater fins through a series of steps such as feeding, rolling, forming, and cutting.

The operation of the entire radiator fin machine is monitored and controlled by an advanced control system. This system can achieve automated production while monitoring the operational status of equipment and product quality in real-time. Once an abnormal situation occurs, the control system will immediately sound an alarm and take corresponding measures to ensure the stability and safety of the production process.

Radiator Fin Machine Workflow

1, Feeding: The radiator fin forming machine is equipped with a precise feeding system, which can accurately feed raw materials into the rolling device of the machine. Because the production speed of this machine is very fast, smooth feeding is a very important task, providing necessary support for the subsequent forming process.

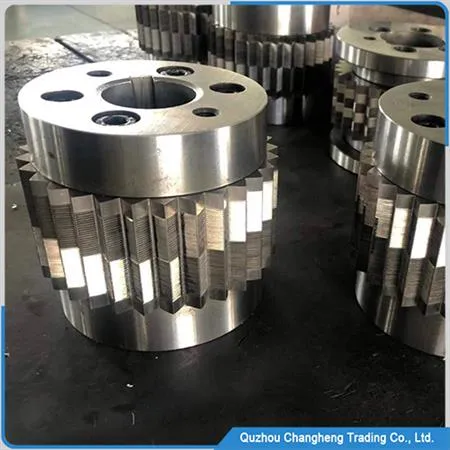

2, Rolling: The raw materials fed into the machine are subjected to rolling treatment to preliminarily form the shape of radiator fins. During the rolling process, the material is gradually transformed into the desired shape through multiple rollers.

3, Forming: The material after rolling treatment enters the forming stage. In this process, the machine precisely presses and controls it to fully meet the design requirements, forming a perfect radiator fin.

4, Cutting: The formed radiator fins need to be cut according to the specified length. The machine is equipped with an automatic cutting device, which is driven by a servo motor and can accurately cut the fins to the required length, ensuring that the size of each fin is consistent.

Technical Data

| No. | ITEM | DATA |

| 1 | External dimensions | 520*90*160cm |

| 2 | Max cutting speed | 60 times/min |

| 3 | Max roller speed | 120m / min |

| 4 | Lubricating oil type | volatile oil |

| 5 | Fin width | 16-150mm |

| 6 | Fin length | any size |

| 7 | Delivery time: | 47 days |

| 8 | Weight: | 1.65T |

application area

- auto radiators

- Truck aluminum intercooler

- Engineering vehicle oil cooler

- Generator aluminum radiator

- Diesel engine cooling

- Household air conditioning condenser

- Automotive aluminum Condensers

- Vehicle air conditioning heater

- Computer radiator

radiator fin machine video

FAQ

A: We designed this machine in two parts, and the length of the packaging box only needs 2.6 meters.

A: Yes, we can send engineers to your factory to install the machine, but you can easily install the machine by following our instructions.

A: Yes, this machine can produce fins for all aluminum and radiators

WECHAT

WECHAT