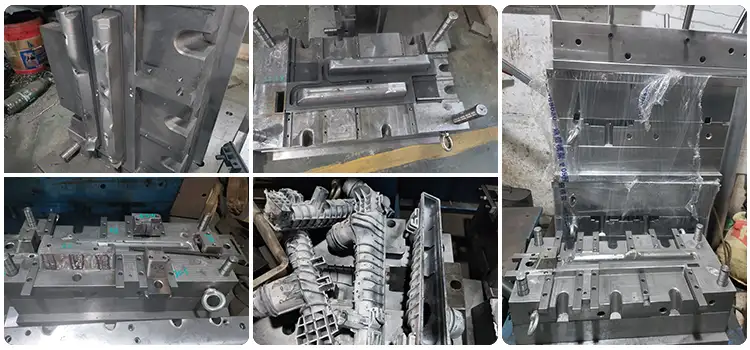

Radiator mold outline

We focus on designing and manufacturing plastic Injection mold for plastic water tanks for automobiles, with years of industry experience and professional knowledge.

Our molds are made of PA66-GF30 material and undergo strict quality control and testing to ensure their durability and stability;

At the same time, we also pay attention to the details and accuracy of the mold to ensure that the plastic water tank injected has a good appearance and performance.

Plastic Injection mold process

- Based on customer needs, design molds to ensure that they meet their requirements and specifications.

- Use high-precision CNC machine tools for mold processing to ensure the accuracy and stability of the mold.

- Conduct heat treatment and surface treatment on the Injection mold to improve its hardness and corrosion resistance.

- Assemble and debug the mold to ensure its normal operation and production of qualified products.

- Conduct quality inspection and testing of the mold to ensure that the quality of the mold meets the requirements.

Plastic Injection mold data

| No. | ITEM | DATA |

| 1 | Surface treatment | Mirror Polish |

| 2 | mold size | Standard Customize |

| 3 | Cavity | 1-2 |

| 4 | Plastic material | ABS/PP/PS/PE PVC/PA6/PA66 |

| 5 | Brand Name | changheng |

| 6 | Origin | Zhejiang, China |

| 7 | mold type | Injection |

WHY CHOOSE US

1. We have a lot of experience in plastic injection mold design.

2, we offer free three-dimensional drawing services for plastic-to-plastic injection mold design.

3, We have two dedicated after-sales teams that can help you with any issues related to the molds and parts.

4, We are ready to sign a contract with you if you need assurance about our plastic molds or plastic parts quality or delivery dates.

5, We have professional plastic injection mold designers and plastic parts production lines, which can provide fast delivery

6, 80% of the mold parts come from factory manufacturing, effectively ensuring the quality of the mold

FAQ

A: Usually, our mold delivery time is 45 working days, and in special cases, it may be 55 working days.

A: Usually, our molds are packed in wooden cases.

A: Our engineers can use CAD, Solidworks, Catia, Inventor, Pro/ENGINEER, ug.

A: The service life of our mold is 300000 times.

WECHAT

WECHAT