Machine Overview

The cross flow heat exchanger production line uses hydraulic presses as the power source, combined with specialized non-standard design and servo motor technology, to achieve automatic handling of raw materials. The design of this production line enables the production of 8 to 12 aluminum plates per minute. In addition, a single mold can adapt to diverse size requirements and provide flexible production options. Our services include customizing molds based on customer-provided designs to meet specific production requirements.

Cross flow heat exchanger production line data

Advantages of the production line

Efficient production

The pressing machine is driven by hydraulic pressure and can produce 8-12 aluminum plates per minute, meeting the needs of large-scale production.

Flexible molds

A mold can produce aluminum plates of various sizes, and this design can provide flexible choices for end users without requiring significant financial investment.

Save electricity

This production line only requires 6.5kw of electricity, which has obvious advantages compared to traditional stamping machine production.

Customized services

We accept molds of any design and can customize them according to customers’ specific needs, providing personalized solutions.

The working principle of the production line

The cross flow heat exchanger production line is a fully automatic production equipment, which consists of a raw material unwinding machine, hydraulic pressing machine, servo moving device, cutting device, and other parts

Its working principle is as follows:,

1, The aluminum plate raw materials are installed on the uncoiler, and the device realizes automatic feeding

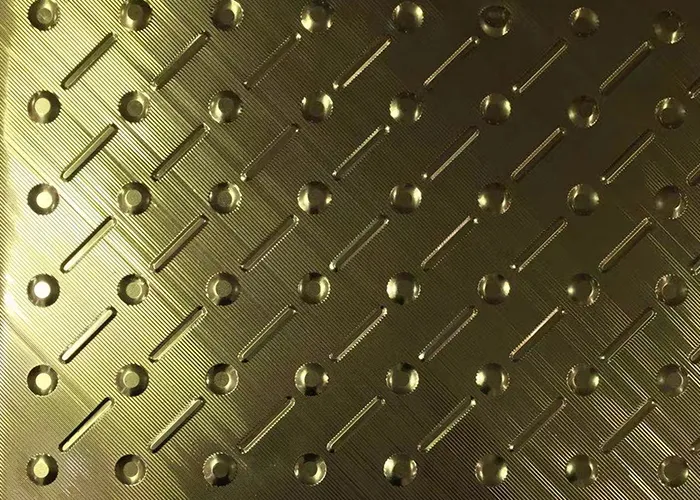

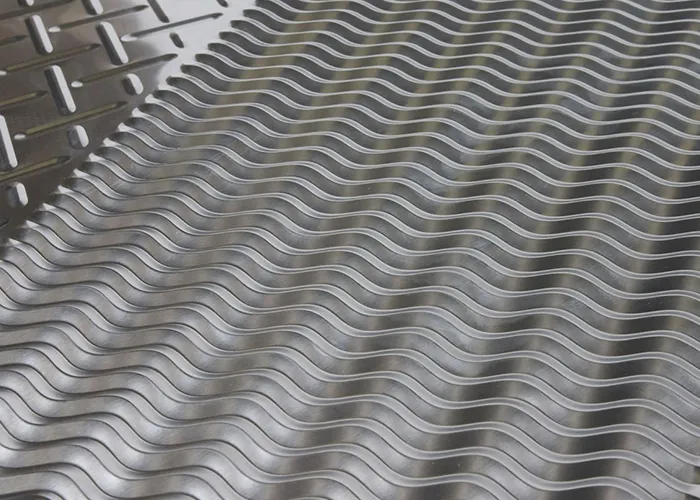

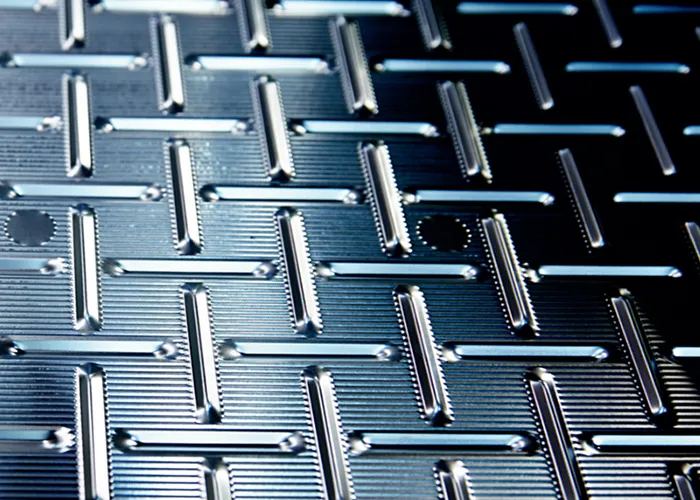

2, The mold is installed on the hydraulic press, and the mold presses the aluminum foil to form a specific pattern

3, After the aluminum foil is pressed into shape, the servo-moving device moves it to the set size,

4, When the aluminum foil moves to the specified length, the cutting device works and cuts the aluminum foil to form a completed aluminum plate

5, Workers manually stack the pressed aluminum foil using tools to form a complete cross-flow heat exchanger core

The entire production process ends here. You can watch the video above to learn more about the details of production

Cross flow heat exchanger production line application

FAQ

A: Our mold design is reasonable; one production line can produce all sizes.

A: The patterns of the molds are different, and the delivery time varies. Usually, the delivery time is 70 days.

A: We provide free technical training services. You only need to pay for the engineer’s travel expenses.

WECHAT

WECHAT