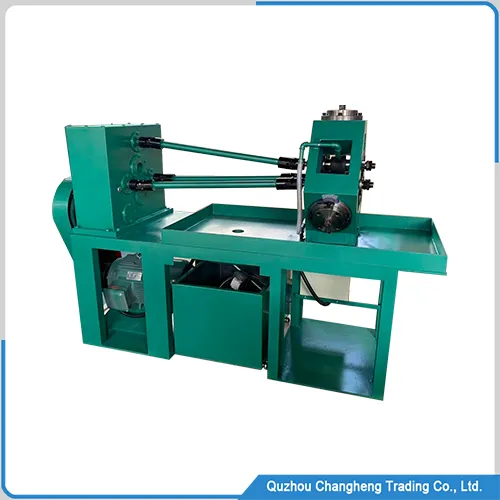

Machine outline

This is a metal fin making machine, which can produce fin of different metals such as copper, aluminum, stainless steel, titanium alloy, etc. The machine has a very wide range of applications, such as electrical industry, new energy industry, heat exchanger industry, etc In the field of industrial cooling, this machine is one of the most critical manufacturing equipment.

This fin manufacturing machine adopts a stable design of four columns, and has a spring as a buffer to achieve high-speed production of 140 presses per minute. In addition, in the high-speed production process, the four columns have automatic supply of lubricating oil to reduce the wear of the cylinder and extend the service life of the machine.

After multiple optimizations and design improvements, this fin machine can now achieve a fully automated production mode, which means that there is no need for workers to participate in the production process, and multiple channels can be produced simultaneously. This not only doubles production efficiency, but also significantly reduces manufacturing costs.

Fin making machine advantages

- Stepless adjustment of production speed

This device uses a frequency converter to control the speed of the motor, achieving infinite variation in production speed. It does not have traditional mechanical gear gears, so there is no need to worry about speed fluctuations and faults during speed changes.

- The structural design of the machine is very compact

We make full use of the internal space of the machine by installing the drive motor at the bottom of the machine and the spindle in the middle. The motor drives the cam movement of the spindle, achieving the movement of the output piston type. This compact design is more reasonable and the output power is stronger.

- Stable fin mass output

The key parts of the fin making machine are all processed by CNC, which effectively ensures the accuracy and tolerance of the parts. The tolerance range of the fin mold is control at 0.001 mm, fully meeting the customers who have high precision requirements for fin dimensions.

- Very convenient daily maintenance

Because this finned machine has an automatic lubrication system, it requires almost no maintenance costs during normal use. After 8 years of use, changing the engine oil is sufficient.

Quick Details

| No. | ITEM | DATA |

| 1 | Feeding speed | 120times / min |

| 2 | Fin materials | iron aluminum stainless steel titanium alloy copper |

| 3 | fin height | 1.5-12mm |

| 4 | max fin width | 300/450mm |

| 5 | aluminum foil | 0.04-0.5mm |

| 6 | Total power | 7.5kw |

| 7 | air source pressure | 0.6MPa |

| 8 | Total weight | 1.8 tons |

Other types of fin machine

Serrated fin machine | wave fin machine

Machine Overview The parts produced by this serrated fin machine are used for heat exchangers and are divided into inner and outer fins. This serrated type of fin is installed inside the aluminum tube, effectively…

Fin tube machine | finning machine manufacturer

Product Description The metal fin tube machine is an upgraded third-generation equipment that can roll single and bimetal finned tubes made of steel, steel aluminum, pure aluminum, copper aluminum, and other metals. It operates smoothly,…

Fin stamping machine of condenser and heat exchanger

Machine outline This high-speed fin stamping machine is an ideal fin production equipment, widely used in the automotive, household appliances, and industrial heat exchanger industries, The working principle of this machine is to achieve high-speed…

Fin roller machine of radiator and condenser

Machine Outline The radiator fin roller machine is the core equipment for processing condensers, radiators, and intercoolers. Its total power is 3.5 kW, demonstrating strong power. More importantly, the fin drum mold’s exceptionally high manufacturing…

Fin making machine working video

Advanced features of fin making machine

- Independent raw material lubrication device, which uses pressure to deliver lubricating oil from the storage tank to the lubrication device. The cotton roller will evenly apply the lubricating oil to both sides of the raw material. This lubrication device has no power and does not require maintenance for life.

- The fin mold of this machine adopts an independent design. Users can replace the fin mold at a low cost to obtain fin of different sizes and shapes. This design can effectively reduce the use cost of users.

- The cutting device can change the blade according to the shape of fin to cut special wavy fin, and can set the length of fin freely without any additional cutting cost.

- This fin production machine uses a 7.5kw motor to output powerful power. It can produce fin of different metal materials, such as copper, stainless steel, titanium alloy, aluminum and galvanized sheet, without any modification of the machine.

Scope of application

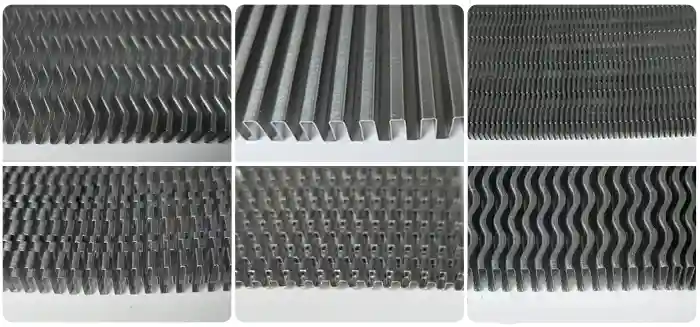

Because this fin making machine can produce a variety of different metal fin, and there are many types of fin, such as serration type, wave type, shutter type, etc., this machine is widely uses in modern industrial production. Here are a few examples

1. The diesel generator needs a water-cooled radiator. This radiator has internal fin and external fin. The size and shape of these two fin are different, and they must use a fin manufacturing machine for production.

2. The current household washing machines all have the drying function, and the electric heating function has a key part that needs to be manufacture by this fin machine, so the thickness of fin is about 0.3mm of aluminum material.

3. The battery thermal management system of the new energy tram has a radiator, and the fin of the radiator needs to be production by the machine.

4. The gear oil inside the double clutch transmission needs to be cooling by the oil cooler. There are many fin inside this oil cooler. This machine is the key machine for the production of this oil cooler fin.

FAQ

A: The delivery time of this machine is 55 days.

A: This machine is packing in wooden cases.

A: This machine is a PLC control system.

WECHAT

WECHAT