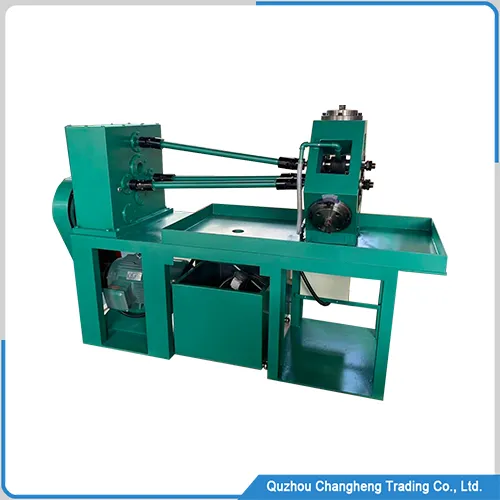

fin pipe machine Features

The metal fin tube machine is an upgraded third-generation equipment that can roll single and bimetal finned tubes made of steel, steel aluminum, pure aluminum, copper aluminum, and other metals. It operates smoothly, has a solid performance, and has a small structure.

fin tube machine advantage

The tool holder body and tool holder use a sophisticated double-round key structure that can support a significant amount of torque and has strong stiffness.

The fin rolling is quick to produce and robust, and the blade is manufactured with precision technology.

Double-row cylindrical rolling bearings are used in the main shaft bearing because they can withstand significant radial forces. have a long lifespan, and are simple to maintain and replace.

The cooling box is separated from the rolling mill by splines. which also links the universal joint and shaft.

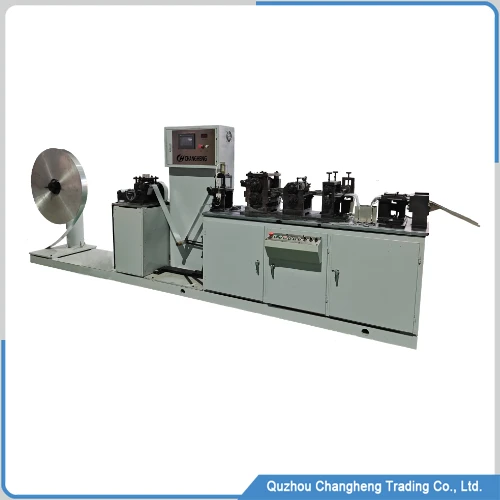

this machine can make these types

Features of fin tube machine

This fin tube device has multiple advantages and brings great convenience to users.

1, It is equipped with a coolant circulation system, effectively avoiding the problem of damage to the blade caused by rapid friction of the roller mold and high temperature. This design not only improves the service life of the equipment but also reduces the risk of production accidents caused by high temperatures.

2, The control system of this finned tube equipment is very simple. There are only three button switches, making the operation exceptionally easy. Even new workers can easily master operational skills through simple training. This undoubtedly improves production efficiency and also reduces the error rate caused by complex operations.

3, This fin tube machine has undergone continuous optimization and design improvements by engineers, making it almost unnecessary for large-scale maintenance and upkeep during use. This will undoubtedly significantly reduce the operating costs of the factory and greatly enhance economic benefits. For factories, reducing the manpower, material resources, and financial investment in equipment maintenance is undoubtedly a major benefit.

4, The cost of roller molds is low, and producing fins of different sizes does not require significant investment. This feature allows factories to flexibly adjust products of different specifications without having to bear excessive cost pressure. While meeting production needs, it effectively controls costs and enhances the competitiveness of the enterprise.

tube fin machine video

Q & A

A: The delivery time of this machine is 45 days.

A: Our machine is following China’s after-sales standards, and its warranty is 12 months.

A: Our machines are packed in wooden cases.

A: We bought ship transportation insurance for the machine.

A: We accept L/C and cash payments.

A: contact us and get the machine catalog

WECHAT

WECHAT