Machine Overview

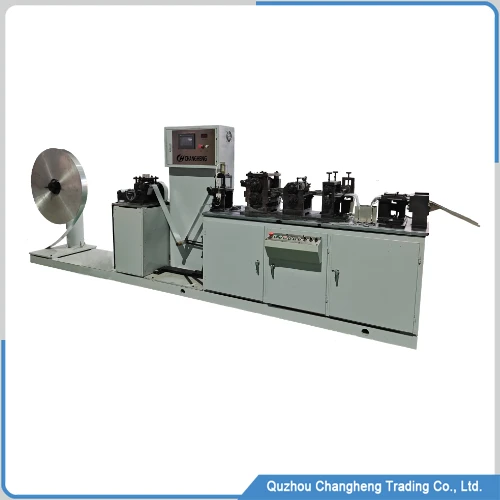

The heat exchanger fin punching machine is a fully automatic production equipment that can produce at a high speed of 144 presses per minute and is widely used in the manufacturing of various sizes of plate and bar heat exchangers.

This punching machine is equipped with an automatic lubrication system, which can ensure the machine’s long service life and stability, while also reducing downtime and maintenance costs.

Independent mold replacement is another advantage of this machine, which makes it more convenient and efficient to produce different types of fins.

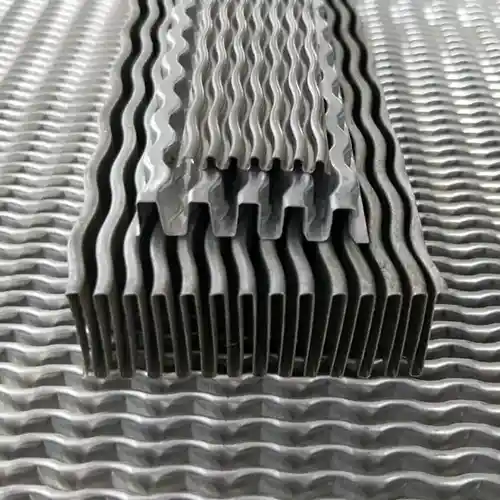

By changing the mold, it is easy to produce sawtooth types, wave types, dimple types, etc Different specifications and shapes of fins to meet different production needs.

This flexibility makes the fin punching machine more competitive in the market and can reduce unnecessary financial waste for heat exchanger manufacturers, as well as bring more business opportunities and profits.

Machine advantages

1, Price competitiveness: 80% of the parts of this machine are manufactured in the factory, so our prices are very competitive

2, Unmanned production: This fin machine is equipped with a fully automatic cutting machine, which can achieve unmanned production

3, Intelligent control: The device is equipped with a 7-inch touch screen, allowing users to input the length and production volume of the fins. After completing the production target, the machine will automatically stop

4, Multi-station production: The maximum width of this fin machine is 300mm. If your fin width is 80mm, the equipment can produce three fins simultaneously, which will greatly improve production efficiency

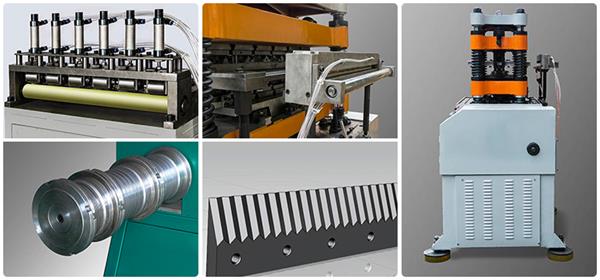

Fin punching machine detail

| No. | ITEM | DATA |

| 1 | Fastest speed | 144/minute |

| 2 | Production type | continuous pressing |

| 3 | Maximum width | 300mm 450mm 600mm option |

| 4 | Fin length control | servo motor |

| 5 | Lubrication type | automatic |

| 6 | Cutting type | cylinder |

In summary, the heat exchanger fin stamping machine is highly efficient, high-quality, stable, and flexible equipment, and its application will bring more advantages and benefits to enterprises. If you are looking for an efficient and reliable fin production equipment, then the heat exchanger fin stamping machine will be your best choice.

fin punching machine video

FAQ

A: The fastest speed of this machine is 146 times per minute

A: This machine is packed in wooden cases

A: Usually, the delivery time of this machine is 56 days

A: Yes, we can provide any type of fin mold, such as wavy, serrated, shutter, dimple

wechat

wechat