Machine outline

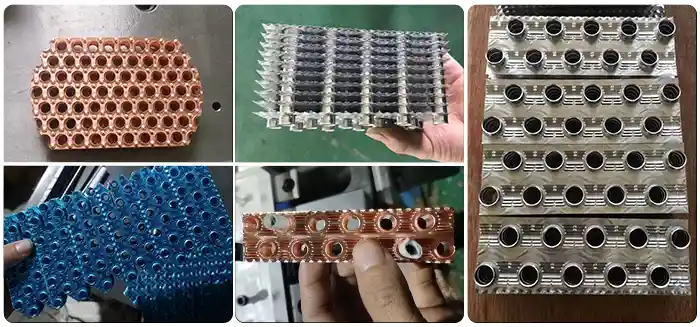

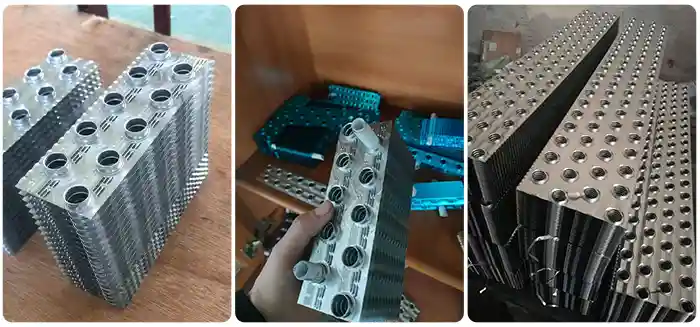

This high-speed fin stamping machine is an ideal fin production equipment, widely used in the automotive, household appliances, and industrial heat exchanger industries,

The working principle of this machine is to achieve high-speed stamping production through the pneumatic drive, allowing the mold to stamp the raw materials of the foil type, forming a fin shape.

The Fin stamping machine mainly consists of a feeding system, a punching system, a lubrication system, a control system, and other parts.

The feeding system is mainly responsible for smoothly and continuously feeding the sheet metal into the punching mold, ensuring the continuity of the production process.

The stamping system is responsible for shaping and punching the raw materials to form the shape of the fins,

The lubrication system is designed to ensure the regular operation of the mold during the punching process and prevent malfunctions caused by rapid wear.

The control system controls equipment operation through computer programs, achieving automated production and improving production efficiency.

Advantages of Fin stamping machine

1, Efficiency:

Due to the use of high-speed punching, production efficiency has been greatly improved.

2, High precision:

Adopting advanced control systems ensures the accuracy of punching and improves the quality of the product.

3, Good stability:

Adopting a long guide rail design and a balancing device ensures the stability of the equipment.

4, High degree of automation:

It can achieve automated production, reduce manual operations, and improve efficiency.

5, Long service life:

Equipped with an automatic lubrication device, it can effectively prevent wear and prolong the service life of the equipment.

Fin stamping machine Quick details

| No. | ITEM | DATA |

| 1 | Speed Adjustment | FDI |

| 2 | Overall size | 650*250*230cm |

| 3 | Main Motor Power | 5.5kw |

| 4 | Outer Material Rolling | 850mm |

| 5 | Inner Material Rolling | Φ75mm |

| 6 | Capacity | 45T |

| 7 | Sucking Length | 100cm |

| 8 | Width of Material | 30cm |

| 9 | Die Height | 20-27cm |

Fin stamping machine video

FAQ

A: To smoothly load the machines into containers, we pack the machines lying down, Our machines are packed in wooden cases.

A: Our after-sales service does not intentionally damage the machine. The warranty is one year.

A: The weight of this machine is about 6.3 tons.

WECHAT

WECHAT