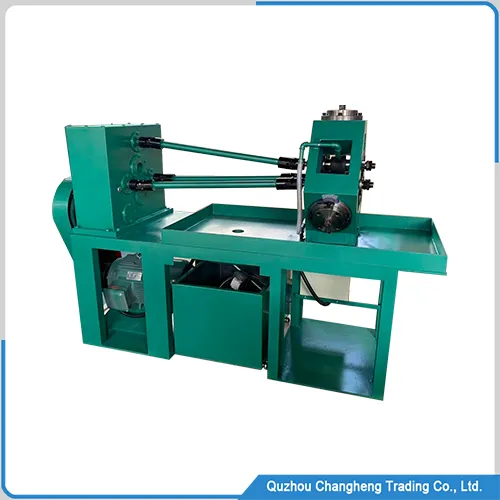

Machine Overview

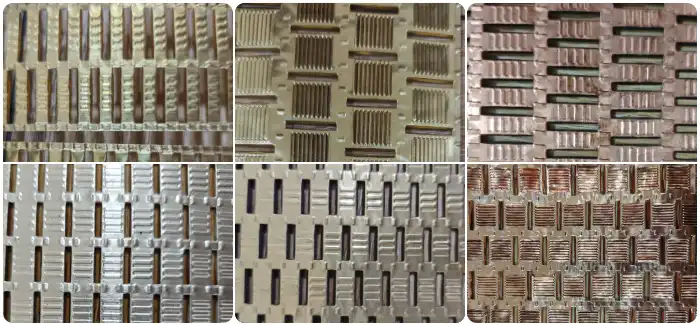

This radiator flat fin machine can produce copper and aluminum materials. The material thickness is 0.035-0.25mm, and its maximum speed is up to 35 meters per minute. At present, this equipment is one of the important production equipment for flat fin radiator.

The machine uses rollers to form fin, and has an automatic lubrication device, which will not produce any waste in the production process. In addition, the independent cutting device is driven by a servo motor, which can precisely control the length of fin, so that each fin can maintain a high consistency.

The size of a roller mold has been scientifically design, which can be compatible with the production of fin of various widths without increasing any cost. This design is very friendly to diversified production plants.

Advantages of radiator flat fin machine

- Modular design

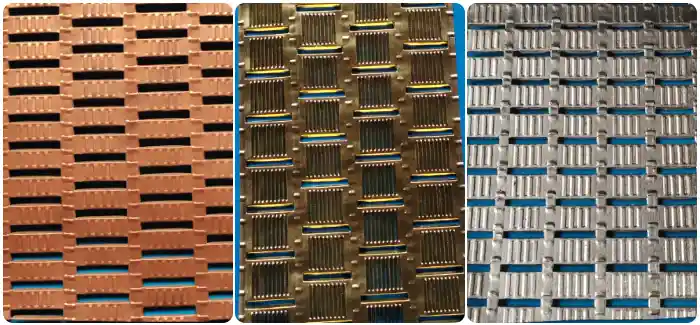

The roller mold of this machine adopts a modular design, which can quickly replace the mold and produce flat fin of different shapes, such as louver type, round bump, linear bump, etc. This design can effectively reduce the use cost and meet the design requirements of different customers for radiator.

- Intelligent control

This machine adopts PLC integrated control and uses touch screen for human-machine interaction. Engineers can preset the production quantity, and the machine will automatically count the production quantity. After meeting the required production quantity, it will automatically stop without the need for manual participation in complex statistics.

- Accurate cutting device

It adopts independent cutting design and servo motor drive to precisely control the length of each fin. The length error of each fin will not exceed 0.05mm, which is far beyond the leveling level of the radiator industry.

- Automatic lubrication system

In the high-speed production process of the flat fin machine, the friction between the roller mold and the fin material will generate a lot of heat, so lubricating oil is needed to cool and lubricate the roller mold. This machine has been configured with this function, and it runs simultaneously with the machine, and fully automated control flow.

Technical data of radiator flat fin machine

- Equipment use: flat fin production

- Control method: PLC + touch screen

- Touch screen language: Chinese and English

- Forming type: Roller rolling

- Fin material: copper, aluminum

- Material thickness: 0.035-0.25mm

- Production speed: 35 meters per minute

- Material width: maximum 280mm

- Fin type: frill

- Fin shape: louver (customized)

- Cut off type: Independent design

- Cut off drive: servo motor

- Power supply: 380V

- Power: 2.5kW

- Dimensions: 160*750*1000mm

- Machine weight: 360kg

Other types of fin machines

Fin roller machine of radiator and condenser

Machine Outline The radiator fin roller machine is the core equipment for processing condensers, radiators, and intercoolers. Its total power is 3.5 kW, demonstrating strong power. More importantly, the fin drum mold’s exceptionally high manufacturing…

Fin stamping machine of condenser and heat exchanger

Machine outline This high-speed fin stamping machine is an ideal fin production equipment, widely used in the automotive, household appliances, and industrial heat exchanger industries, The working principle of this machine is to achieve high-speed…

Fin making machine for industrial production

Machine outline This is a metal fin making machine, which can produce fin of different metals such as copper, aluminum, stainless steel, titanium alloy, etc. The machine has a very wide range of applications, such…

Fin tube machine | finning machine manufacturer

Product Description The metal fin tube machine is an upgraded third-generation equipment that can roll single and bimetal finned tubes made of steel, steel aluminum, pure aluminum, copper aluminum, and other metals. It operates smoothly,…

Radiator flat fin machine working video

Installation and precautions

- This flat finned machine adopts an independent design, and one machine is a whole, so its installation is very convenient and there is no complicated installation process. If the factory floor is uneven, engineers only need to adjust the foot screws to keep the machine flat and stable.

- This machine is driven by three-phase electricity and requires a professional electrical engineer to connect the power supply to avoid accidents.

- The first time running the machine, it needs to be operated at low speed in manual mode to ensure smooth operation.

- Before normal production of the machine, it is necessary to check that there are no tools, screws, or items unrelated to production in any position of the machine, as there may be slight shaking during high-speed operation. If any items fall into the roller mold, it will cause irreversible damage to the mold.

Final summary

This flat fin machine is one of the most popular radiator production machines at present. It not only has a high production speed and stable quality output, but also has very good price competitiveness. If you are really looking for this machine to expand your production, we should be your good choice.

We can design various types of fin and different sizes of flat fin for you, and provide necessary technical support in the production process. Now you can send an email to our engineers to get more details about this machine.

WECHAT

WECHAT