Machine Overview

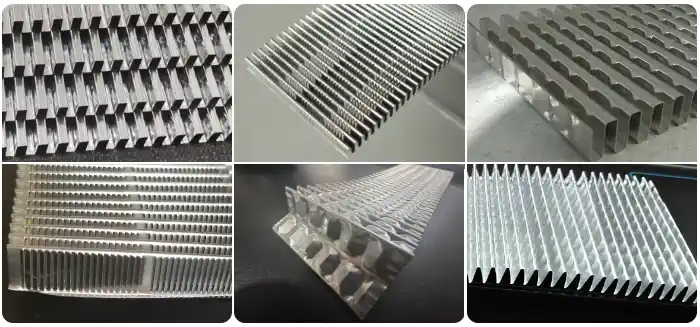

This radiator fin machine is an advanced production equipment widely used in various fields, including the automotive, truck, and engineering vehicle industries. This equipment efficiently produces high-quality radiators, condensers, and heater fins through a series of steps, including feeding, rolling, forming, and cutting.

An advanced PLC control system monitors the operation of this radiator fin machine throughout the process. This system enables automated production while continuously monitoring the operational status of equipment and product quality in real-time. Once an abnormal situation occurs, the control system will immediately sound an alarm and take corresponding measures to ensure the stability and safety of the production process.

Radiator Fin Machine Workflow

- Feeding: The radiator fin forming machine is equipped with a precise feeding system that accurately feeds raw materials into the machine’s rolling device. Due to the machine’s high production speed, smooth feeding is a crucial task, providing essential support for the subsequent forming process.

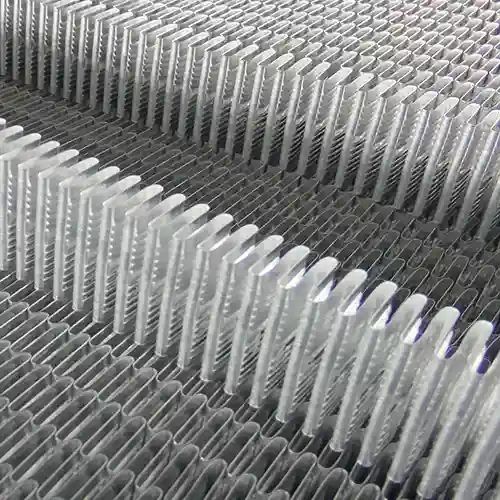

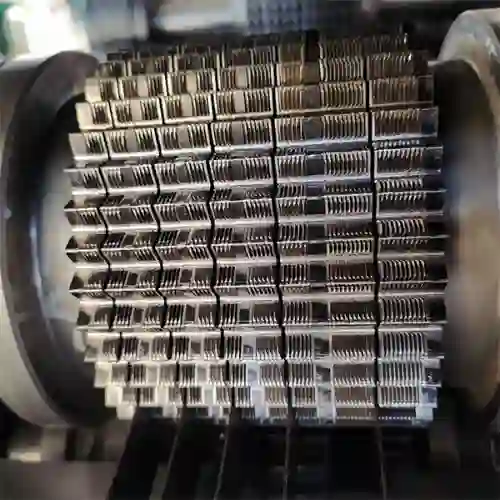

- Rolling: The raw materials fed into the machine undergo rolling treatment to form the preliminary shape of the radiator fins. During the rolling process, the material is gradually transformed into the desired shape through the action of multiple rollers.

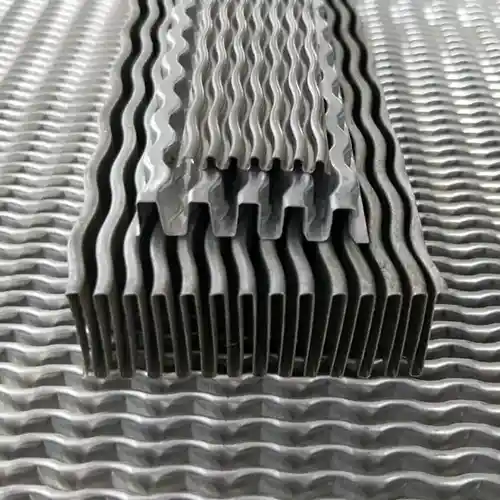

- Forming: The material after rolling treatment enters the forming stage. In this process, the machine precisely presses and controls it to fully meet the design requirements, forming a perfect radiator fin.

- Cutting: The formed radiator fins must be cut to the specified length. The machine is equipped with an automatic cutting device, driven by a servo motor, which accurately cuts the fins to the required length, ensuring consistent fin sizes.

Technical Data

Application area

- auto radiators

- Truck aluminum intercooler

- Engineering a vehicle oil cooler

- Generator aluminum radiator

- Diesel engine cooling

- Household air conditioning condenser

- Automotive aluminum Condensers

- Vehicle air conditioning heater

- Computer radiator

Radiator fin machine video

Other types of fin machines

Radiator fin rolling machine

Device outline The Radiator fin rolling machine is an automated equipment used for producing radiator fins, which mainly consists of feeding, rolling forming, cutting, and other parts. The feeding section is responsible for feeding the aluminum foil raw materials into…

Radiator fin machine supplier and manufacture

Machine Overview This radiator fin machine is an advanced production equipment widely used in various fields, including the automotive, truck, and engineering vehicle industries. This equipment efficiently produces high-quality radiators, condensers, and heater fins through a series of steps, including…

Radiator fin forming machine

Machine Overview The radiator fin forming machine is an efficient and high-speed specialized piece of equipment primarily used for producing radiator fins. This type of equipment utilizes continuously variable speed technology, enabling stable operation at high speeds and significantly improving…

Oil cooler fin machine for aluminum heat exchangers

Machine Overview The oil cooler fin machine is an advanced continuous production heat exchanger equipment that adopts a continuous production method and can achieve fully automatic production without human supervision, By replacing low-cost molds, various shapes of aluminum fins can…

Radiator fin machine advanced features

Intelligent control system

The parts of this machine’s control system are all from internationally renowned brands. Engineers can preset production plans through the touch screen. When the machine meets the production requirements, it will automatically stop and give a warning. Moreover, the machine is equipped with multiple sensors to monitor its smooth operation in real time. Suppose the machine encounters problems, such as a lack of raw materials, a shortage of volatile oil, or low compressed air pressure. In that case, it will automatically stop running and display an alarm, with the touch screen showing the corresponding fault code.

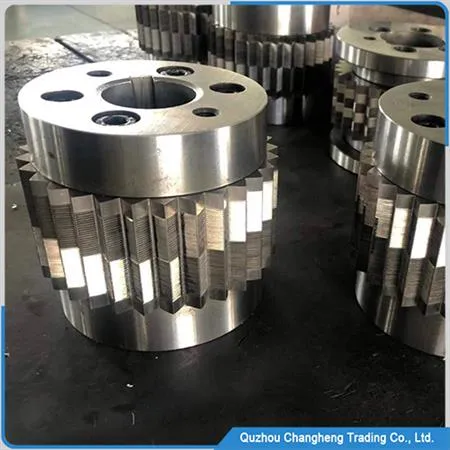

High-precision CNC manufacturing

The aluminum fins produced by this machine must not have a size error greater than 0.02 mm, which places higher demands on mold manufacture. Therefore, the roller molds and other key parts of this machine are all machined using high-precision CNC machines. The roller blades also require a grinding process to ensure that their size meets the high-precision requirements.

High-quality materials

For the smooth operation and longer lifespan of the fin machine, the blade of the mold is made of M36 metal, which has a high cobalt content. This metal not only exhibits excellent wear resistance but also possesses good toughness, ensuring that the roller mold will not easily wear out or break during high-speed operation.

Another feature of this metal is that it doesn’t rust easily, even in highly corrosive environments. The blade of the roller mold can still maintain its brand-new condition.

For more information about the advanced features of this radiator fin machine, don’t hesitate to get in touch with us by clicking the button below and sending an email. Our engineers will contact you directly and provide you with the technical documents for this machine, as well as additional details about the machine.

FAQ

A: We designed this machine in two parts, and the packaging box length only requires 2.6 meters.

A: Yes, we can send engineers to your factory to install the machine, but you can also easily install it by following our instructions.

A: Yes, this machine can produce fins for all aluminum and radiators

WECHAT

WECHAT