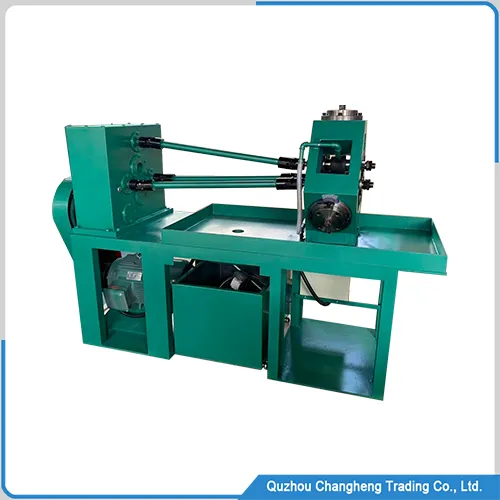

Machine Overview

The radiator fin forming machine is an efficient and high-speed specialized piece of equipment primarily used for producing radiator fins.

This type of equipment utilizes continuously variable speed technology, enabling stable operation at high speeds and significantly improving production efficiency.

This device is equipped with an automatic lubrication system, which effectively lubricates the roller mold, reduces wear, and extends the machine’s service life.

At the same time, the servo motor drives and controls the length of the fins, enabling precise fin length adjustment and ensuring the production quality and consistency of the fins.

The 7-inch touchscreen equipped with this radiator fin forming machine provides engineers with an intuitive and convenient operating interface.

Through this screen, engineers can monitor the production process in real-time and control the length of fins according to production requirements.

This function makes the operation of fin forming equipment more flexible, meets the changes in different production needs, and improves production efficiency and quality.

At the same time, the design of the touchscreen also enhances the usability of the equipment, allowing even workers without professional training to get started, thereby reducing production costs quickly.

Radiator fin forming machine data

| No. | ITEM | DATA |

| 1 | max speed | 120m/min |

| 2 | max cutting | 60times/min |

| 3 | raw material | aluminum copper |

| 4 | material thickness | 0.05-0.15mm |

| 5 | Delivery time | 55 days |

| 6 | Fin height | 4.5-15mm |

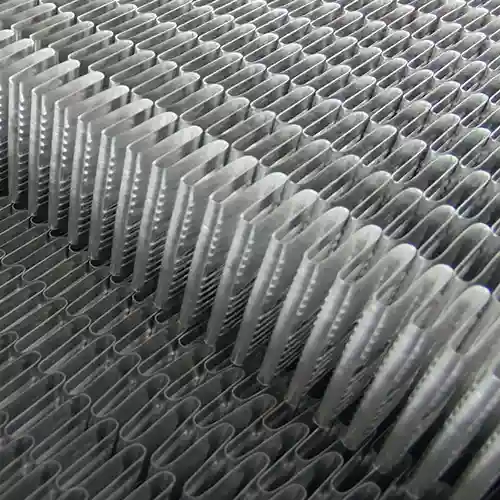

| 7 | Fin type | Louver |

| 8 | Length control | servo motor |

Radiator fin forming machine application

- Automotive aluminum radiator

- Household air conditioning condenser

- Truck intercooler

- Generator cooler

- Car air conditioning condenser

- Automobile evaporator

- Computer radiator

- Air compressor radiator

Fin forming machine working video

Features of the fin forming machine

- The roller mold of this machine features an independent design, allowing users to replace different roller molds according to various fin shapes and sizes. This enables a significant reduction in investment and increased economic benefits for the factory.

- The height of the machine’s workbench is designed according to ergonomic principles, allowing workers to operate the machine while standing or sitting on an ordinary stool. Of course, they can also work while sitting in an electric wheelchair, which means this machine does not limit the workers’ freedom of work in any way.

- To meet customers’ demand for a broader range of fin sizes, we offer a multi-size roller mold that can accommodate various widths, including 16mm, 26mm, and 48mm, among others. This design is suitable for radiator factories in the aftermarket. These rollers not only meet the production needs for multiple sizes but also eliminate the complex process of mold replacement.

FAQ

A: Yes, it can produce copper materials.

A: The default color is gray-white, and you can also customize its color.

A: The training for this machine takes about 2-5 days, which is enough.

WECHAT

WECHAT