Machine Overview

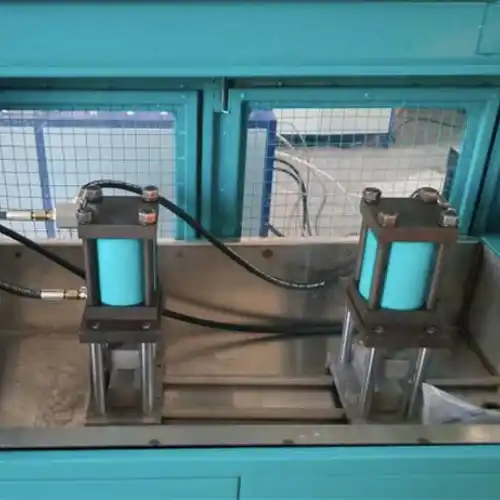

This is a tube testing machine that uses two hydraulic cylinders to clamp the front end of the pipe and then inject pressure into the inside of the pipe to check whether the pressure resistance of the pipe meets the requirements.

This machine is usually uses as a high-frequency welded aluminum pipe pressure blasting testing equipment, in the radiator, condenser, intercooler and evaporator of automobile engines, etc., for the limit stress testing of the pipes required for these products

This aluminum tube testing machine is a multi-purpose design, and flexible tools can meet the stress testing of different tube types, such as round tubes, flat tubes, micro-channel tubes, and tubes of different metal materials. Its unique design has a very wide range of uses

Tube testing machine technical parameters

| No. | ITEM | DATA |

| 1 | Aluminum tube | φ 16~ φ 50mm |

| 2 | Wall thickness | 0.6-2.5mm |

| 3 | Burst pressure | 50 MPa |

| 4 | Measurement accuracy | ≤ ± 0.5% |

| 5 | Testing length | 100-900mm |

| 6 | Control mode | Computer control |

| 7 | Tube long side | 30-90mm |

| 8 | Tube short side | 3-40mm |

Tube testing machine working principle

This machine mainly uses compressed air as the power source to drive the hydraulic cylinder to achieve pressure output, and its maximum pressure reaches 50MPa.

Engineers can achieve accurate pressure control by inputting compressed air flow, adjusting valves, ensuring accurate data for every test, and continuously improving product design and production processes

The test data is displayed in the form of curves on the computer, allowing engineers to visually check pressure changes. Test reports are output in Word and PDF formats to enable multi-department sharing of test results, improve work efficiency, and achieve rapid progress of the project

Radiator tube testing machine Characteristics

- Pneumatic booster design

This machine does not require a hydraulic station to provide power; it not only saves power but also has a maximum output pressure of 50MPa, which can test pipes of any shape and metal

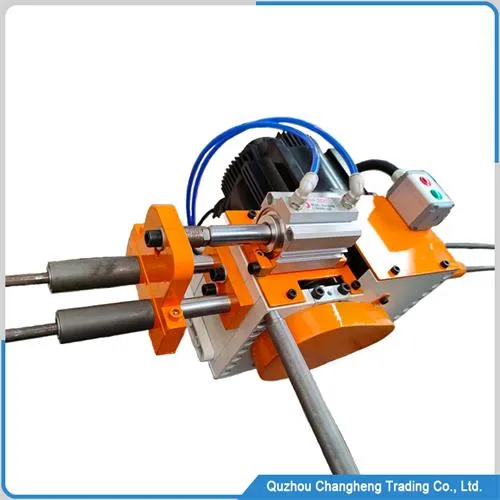

- Free high-pressure pipe connection

The tools and stress testing equipment of the test machine are connect by high-pressure pipes, and the different pipes can be freely changed. This design is not only simple and flexible to use, but also very easy to maintain.

- Industrial computer control

This testing device has an industrial computer, using the Windows 10 operating system, and the testing software has two languages, Chinese and English. Each test result can be directly print or output PDF file.

- Security protection

The test tube machine is equipped with a protective cover, which is made of plexiglass and a steel structure, of which the steel plate is hollow, and laser welding technology is used to ensure the safety and reliability of the explosion test

- Multi-valve control

This machine has multiple valves, and engineers can freely and accurately adjust the pressure. It can test different sizes of aluminum tubes.

WECHAT

WECHAT