Machine Overview

This tube cutting machine integrates automated pipe straightening, cutting, and storage equipment. It uses a burr-free cutting technology, and the incision has a 0.5mm rounded corner and is smooth without burrs. It is specifically designed for metal pipe processing in the HVAC industry.

The equipment uses servo motors and PLC intelligent control, supporting 5-20mm metal tube diameters. This size range can cover the entire refrigeration industry. One device has 4-10 channels, and each tube cutting channel can operate independently. Therefore, users can set different diameter sizes for each channel to meet various application scenarios.

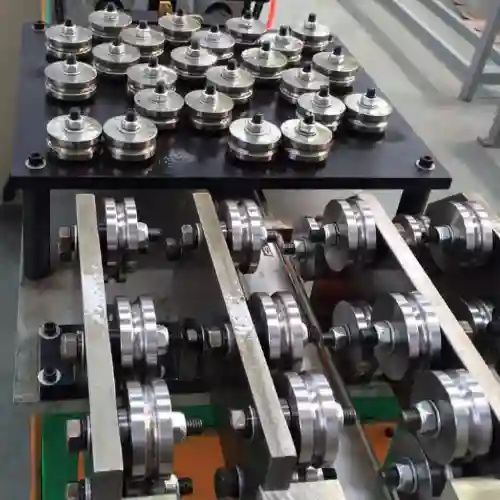

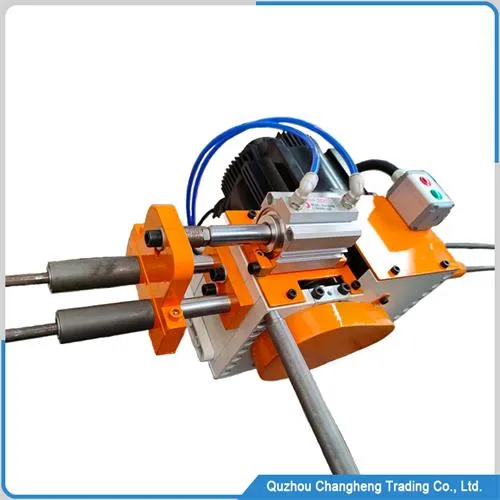

The machine is driven by a servo motor that rotates the screw. The screw outputs a powerful force to drive the cylinder to tighten the metal tube and move it forward. The tube goes through multiple sets of rollers for 360-degree straightening, and then it is cut. Due to the accuracy and reliability of the servo motor, the error in cutting length will not exceed 0.01mm.

The tube cutting machine advantages

- Precise cutting control

The movement of the tube relies on the drive of the servo motor, ensuring the consistency of products in mass production. The tolerance of the cutting length is ≤0.3mm/1000mm.

- A cutting technique without burrs.

The tube cutting doesn’t have any burrs, and the incision will have a 0.5mm reduced round corner, which helps the tube insert into the fin hole.

- Highly automated production.

The machine unloads materials from the tube, straightens, cuts, and stores them. It operates fully automatically throughout the process. If it encounters any abnormal situations, it will automatically sound an alarm. It will automatically stop when it completes the set production tasks.

- Strict environmental protection requirements.

This cutting machine does not emit any pollution during the production process, and metal copper pipes do not require any lubricating oil during processing. Therefore, the copper pipes that have been cut do not need to be cleaned, and they can be used directly.

Tube cutting machine technical data

| No. | ITEM | DATA |

| 1 | Tube material | Copper, aluminium |

| 2 | Tube wall thickness | 0.3-1 mm |

| 3 | Workstation | 4-10 optional |

| 4 | Feeding | Automatic |

| 5 | Production speed | 3m/min |

| 6 | Drive mold | Servo + pneumatic |

| 7 | Weight | 1.5T |

| 8 | Diameter range | 4-20mm |

| 9 | Cutting type | No Burr |

| 10 | Length range | 50-6000mm |

| 11 | Straightness tolerance | ≤2‰ |

| 12 | Compressed air | 0.4-0.6 MPa |

Application scenarios of tube cutting machines

- Heat exchanger industry: Batch cutting copper pipes for Evaporator and condenser, producing products that meet higher requirements for straightness.

- The automobile manufacturing industry: This machine is compatible with copper and aluminum tubes, and can process oil tubes and refrigeration tubes. It can adapt to tube wall thicknesses of 0.3-1mm.

- Heavy industry: The maximum tube diameter of this cutting machine is 20mm, and it can be applied in the industrial field of heat exchangers as well as meet the needs of pipelines with special requirements.

- Medical industry: Medical gas tube, tube for high-cleanliness precision instruments, and fields that require high precision for tubes, etc.

Tube cutting machine working video

Advanced features of the tube cutting machine.

Simple and convenient adjustment.

The wheel straightening machine has high-quality bearings and up, down, left, right, and multi-dimensional straightening functions. It can automatically optimize the straightening parameters for tubes of different hardness, and switch raw materials without manual calibration.

Longer maintenance design.

The cutting blade is made of chromium steel (HRC50 hardness), and after cutting, the blade is cooled by compressed air, which prolongs its lifespan.

Independent operation of a single channel.

This tube cutting machine can run multiple workstations at once, or one workstation at a time, and this design can meet the diverse production needs of customers.

Intelligent control system.

The PLC and touchscreen have a human-machine interface, and there are multiple languages, languages to choose from. Users can monitor the operating parameters of the equipment in real time. It also supports switching production programs for different pipe diameters in one step.

Other HVAC machines

Tube bending machine for heat exchangers

Machine Overview In the heat exchanger manufacturing industry, many U-shaped hairpin tubes are needed. Traditional U-tube bending machines rely on hydraulic stations for drive, which consume a lot of energy and generate a lot of noise. It isn’t easy to…

Water pressure Tube expanding machine

Machine Overview The water pressure Tube expanding machine is special equipment useing in the heat exchanger industry. It consists of a control system, a pressurization system, and special tools for pipes. The water pressure expansion machine have a 7-inch touch…

Convenient Portable tube expander

Machine contour A servo motor drives this portable tube expander, easily expanding pipes into various required sizes. Its easy-to-use touchscreen interface makes it convenient for users to operate and set up. This portable expansion machine is suitable for producing large…

FAQ

A: The fastest delivery time is 45 days. Customized equipment requires more time.

A: Microchannel aluminum tubes with arbitrary holes.

A: It has two languages, Chinese and English.

WECHAT

WECHAT