Product Overview

This plastic injection mold is a special tool for the production of radiator tanks. Its internal cavity is designed according to the characteristics of automobile radiators. When the material is injected into the cavity, it forms the desired shape and size after cooling.

This mold features a hot runner and a cooling water channel, which can quickly cool, thereby improving production efficiency. Additionally, the mold cavity has been polished with high precision, and the surface of the radiator tank.

We have been in the automotive manufacturing industry for approximately 20 years, specializing in the design and manufacture of radiator plastic tank molds. Our focus is on providing customers with high-precision and long-lasting molds.

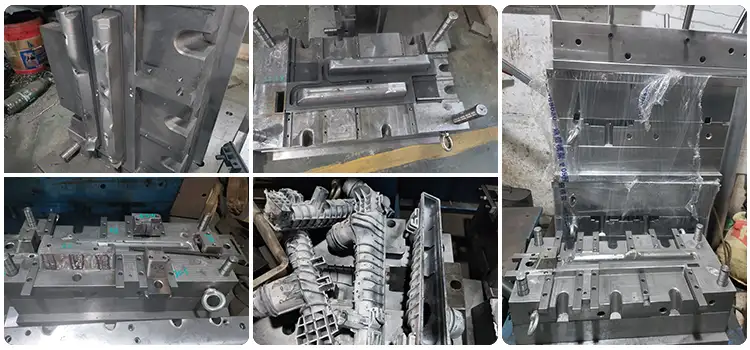

Plastic injection mold manufacturing process

Our molds use CNC machinery, high-precision automated production, and combined with a systematic manufacturing process, we strictly adhere to high-standard manufacturing processes to ensure the quality and size of the molds. The following examples illustrate our manufacturing characteristics

Design and planning

We design the plastic mold based on the customer’s radiator plastic tank structure, as well as the material properties and production efficiency, so that the structure and size of the mold meet all the customer’s requirements

Precision machining

80% of the parts of this mold are CNC precision machining, especially key parts such as molds and cores, which must be precisely polish and sanded to ensure that the fit of each part meets high-precision standards

Part hardening heat treatment

Ordinary parts are quenching in a vacuum to increase their hardness and extend the service life of the plastic injection mold. Key parts such as the mold core are plated with Luo treatment, and the surface hardness reaches 62 while reducing its deformation

Assembly and commissioning

Assembling molds requires experienced engineers to complete; some parts need to be hand-polished, and then the energy can meet the design standards and requirements. Our team of engineers has an average of 15 years of work experience and can easily complete these tasks

Quality and testing

When the mold is assembled, it needs to be clamped and tested, and then installed on the injection machine for production. Usually, our molds are trial-produced about 100-300 times in the factory in China, and each product is perfect before it can be packaged and delivered.

Plastic Injection mold data

| No. | ITEM | DATA |

| 1 | Surface treatment | Mirror Polish |

| 2 | mold size | Standard Customize |

| 3 | Cavity | 1-2 |

| 4 | Plastic material | ABS/PP/PS/PE PVC/PA6/PA66 |

| 5 | Brand Name | changheng |

| 6 | Origin | Zhejiang, China |

| 7 | mold type | Injection |

Design features of plastic injection mold

- We design the size shrinkage rate of the mold cavity according to the characteristics of the raw material PA66-GF30 to meet the size of the plastic tank and meet the customer’s requirements.

- Engineers rely on SolidWorks, pro/E and other design software to optimize the design of the hot runner, efficient cooling channel distribution, and ensure the production efficiency of this plastic tank mold.

- The important location adopts a modular structure, allowing the replacement of single modules to produce different products. This design effectively reduces costs and increases a lot of flexibility.

- A reasonable demoulding structure design not only ensures the beautiful appearance of the plastic tank, but also significantly improves the quality of the product.

Why choose our plastic injection mold?

- We only focus on plastic tank molds for automotive radiators, and we have accumulated a lot of design experience because of our focus. We have a lot of successful cases and supply these molds to more than 200 factories around the world

- Fast delivery time, conventional radiator plastic tanks, the fastest delivery time is 45 days, multi-module and complex plastic tanks, their delivery time is 55 days, our delivery time far exceeds competitors

- With an independent design team, you only need to provide samples or 3D models, and our team can design a perfect radiator tank plastic injection mold for you. Sometimes you only need to provide the OEM number of the radiator, because no one is more professional than us in this field

- Each mold will undergo rigorous testing in China, fully meeting all requirements, and then it will be delivered to the customer, and free plastic samples will be provided to the customer for size and quality confirmation.

- The packaging is wood that has been fumigation at high temperature, which not only meets the transportation safety of the mold, but also meets international logistics standards, providing convenience for your customs clearance

FAQ

A: Usually standard design, the service life of this mold is 300,000 times. If you have higher requirements, we can increase durability according to demand.

A: We are a supplier of molds for manufacturing. If you need raw materials, we can ask the raw material manufacturer to contact you and provide you with raw materials.

A: The material of the die core is P20, which has high wear resistance. The other material is 45 #steel, which has good cost performance.ENGINEER, ug.

WECHAT

WECHAT