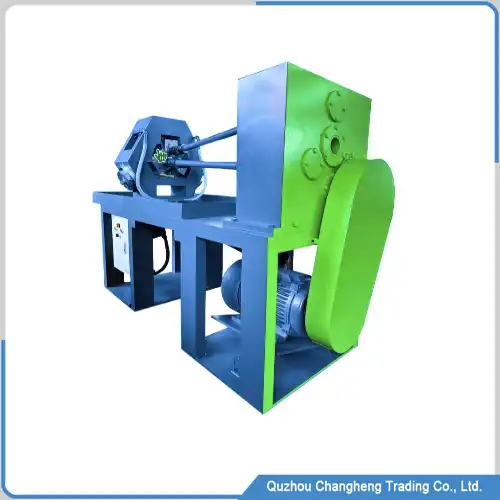

Machine Overview

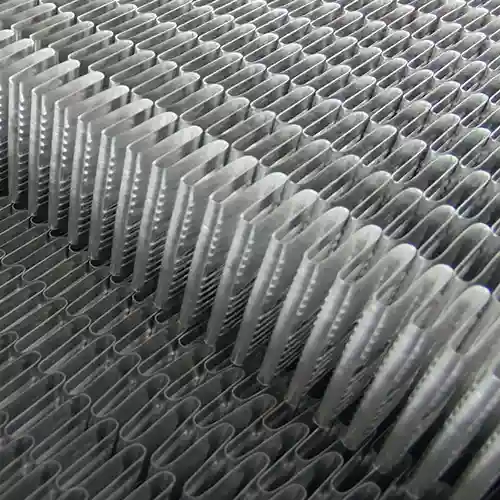

The condenser fin machine adopts a roller production method, which can produce the louver shaped fins required for microchannel condensers with extremely high efficiency.

This machine can produce up to 120 meters of fins per minute, demonstrating significant advantages in production efficiency.

Due to its excellent performance and reliable quality, this machine has gained widespread market recognition.

This machine is equipped with advanced control systems that can accurately control various parameters in the production process, ensuring the dimensional accuracy and shape consistency of the fins.

In addition, the roller mold of this machine can with multiple width sizes, and this combination type of mold can produce more different types of condensers, saving a lot of money for the factory’s later investment

Condenser fin machine data

| No. | ITEM | DATA |

| 1 | Fin material | aluminum copper |

| 2 | Fin type | Louver, straight |

| 3 | Fin height | 3.5-12mm optional |

| 4 | Roller mold | multiple sizes |

| 5 | Fastest speed | 120 m/min |

| 6 | Appearance | optional colors |

| 7 | Interactive languages | Chinese and English |

| 8 | Aluminum foil thickness | 0.05-0.15mm |

| 9 | Fin length | Any length |

| 10 | Aluminum material | 3003 4343/3003/4343 |

Components of condenser fin machine

- Raw material unwinding device

This device is responsible for unfolding the metal material in the coil and preparing for subsequent processing. It has a magnetic motor to constrain the rolling speed and adapts to a production speed of 0-120 meters per minute.

- Aluminum foil conveying device

It smoothly and quickly transports unrolled metal materials to the forming area, automatically adjusting the tension of the rollers according to the production speed to ensure a continuous and stable supply of materials during the processing.

- Louver Forming Device

Aluminum foil is processed into louver shaped fins through specific roller molds.

This step is the core link in the production process of condenser fins. Our machine’s roller mold adopts an independent design, and changing the roller mold can achieve the production of fins of different sizes.

- Automatic cutting device

Users only need to set the length of the fins through the touch screen, and this machine will automatically cut the required length. As this cutting device is driven by a servo motor, it can effectively ensure the consistency of each fin length.

- Control System

The brain of the condenser fin machine is responsible for coordinating the actions of various components to ensure precise control of the production process.

Control systems typically include PLC programming controllers, human-machine interfaces (HMI), and various sensors used to monitor various parameters in the production process.

- Lubrication System

Provides necessary lubrication for the moving parts of the machine, reduces wear, extends machine life, and ensures smooth production processes.

These components work together to form a complete automated production line that can efficiently, continuously, and stably produce high-quality condenser fins to meet the production needs of microchannel condensers.

Condenser fin machine working video

Condenser fin machine advantage

- Highly automated production

This fin machine is a highly automatic production equipment, where aluminum foil raw materials are fed, formed, and cut without the involvement of any workers, and it produces at an astonishing speed

- High precision manufacturing technology

The fin roller mold adopts high-precision manufacturing technology, and the error of the fins is control within 0.01mm, which is currently the highest level of precision in industrial manufacturing

- There is an air purification system

This fin machine requires lubrication to be sprayed on the roller mold during the production process, ensuring that the roller mold remains lubricated during high production. Therefore, we have designed an air purification system for this machine to ensure that the lubricating oil will not spread due to high-pressure spraying, affecting the air in the workshop

FAQ

A: Its thickness should not exceed 0.05mm and should be able to produce.

A: Usually, its aluminum material is 4343/3003/4343.

A: It is a transparent volatile oil.

WECHAT

WECHAT