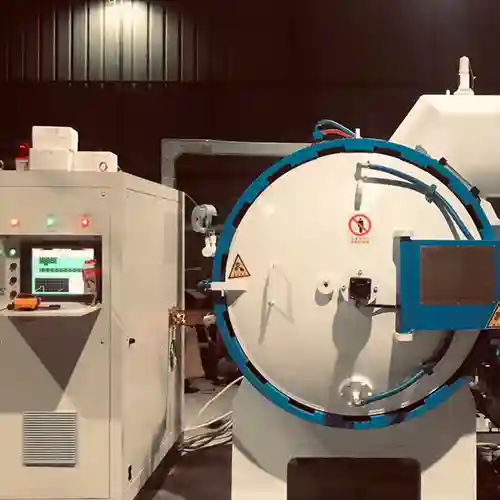

Machine Overview

The aluminum vacuum brazing furnace is specialized equipment in the heat exchanger industry. It is designed with a horizontal single door, and the inside of the chamber is equipped with a load-bearing beam, an additional unit, a heat insulation device, a cooling circulation pipeline, and other components.

The entire vacuum furnace is a complex system, which includes the whole furnace body device, vacuum system, water cooling system, electrical control system, pneumatic system, and loading vehicles outside the furnace etc. Among them, the vacuum pump is one of the most important parts. This vacuum furnace needs multiple vacuum pumps to work together, such as vacuum pumps, diffusion pumps, Roots pumps, etc.

This vacuum furnace is for high-temperature welding of aluminum materials, so it needs a higher vacuum pressure to ensure that aluminum materials do not oxidize and deteriorate in a high-temperature state. Moreover, this vacuum furnace also has the function of nitrogen protection to prevent sudden power outages from causing the vacuum pressure to disappear, resulting in unnecessary losses. Nitrogen is an inert gas that effectively ensures that aluminum materials do not oxidize or deteriorate.

The furnace body is design with two layers of metal plates. The inner wall is 8mm 316L stainless steel, and the outer wall is 10mm carbon steel. An independent pipeline in the interlayer allows cooling water to flow, ensuring the temperature does not spread outward, and keeping the factory workshop at a suitable temperature.

Vacuum Brazing Furnace Quick Details

| No. | ITEM | DATA |

| 1 | Warranty time | 1 Year |

| 2 | Usage | Aluminum Brazing |

| 3 | Chamber size | Customised |

| 4 | Operating temperature | 620-650℃ |

| 5 | Heating Rate | 0-20℃/min |

| 6 | Certificate | CE |

| 7 | Max temperature | 750℃ |

| 8 | country of origin | China |

| 9 | Temperature uniformity | ≤±3℃ |

| 10 | Temperature control accuracy | ≤±1.0℃ |

| 11 | Heating speed | 0~25℃/min |

| 12 | Ultimate vacuum | ≤5×10-4 Pa |

| 13 | Backfilling pressure | 0~0.9 Bar |

| 14 | Controlling method | PLC+industrial computer |

| 15 | Recording method | Paperless recording |

Vacuum Brazing Furnace Features

- Heating Power supply The control cabinet is install above the furnace body, saving the factory’s use space, and the outside of the furnace body has a maintenance platform, guardrail and safety stairs, which is convenient for later maintenance and repair.

- The heat insulation barrier in the furnace have 4 layers of stainless steel material. The thickness of the materials from the outside to the inside is 0.5mm for the first 3 layers, and 1mm for the fourth layer. This design can effectively prevent the temperature from spreading outward, ensuring a higher temperature uniformity.

- There are heating units on all six sides of the furnace, and each heating unit can independently control the temperature. This design has very obvious advantages. It improves the heating speed and enhances the uniformity of temperature.

- All the vacuum pumps of this vacuum furnace are from internationally renowned brands. At the same time, pneumatic valves, electronic detection parts, pressure gauges, and other parts are installed on the vacuum pipeline, and the real-time changes of vacuum pressure are monitored throughout the process.

- The diffusion pump adopts a direct-through structure design, effectively reducing the travel of cooling water and preventing the diffusion pump from having lubricating oil return.

- The water cooling system has an electric pressure gauge. In case of insufficient water pressure, the control system will automatically alarm and lock to protect the safety of the equipment.

Cooling system

1. This vacuum brazing furnace has a water circulation system. It can effectively cool the furnace body, maintain the temperature of the furnace body within a safe range, and avoid overheating and damage.

By circulating water flow, the heat generated by the furnace body can be effectively absorbed and taken away, maintaining a stable temperature inside the furnace.

2. When it is necessary to reduce the temperature of the furnace body, this water-cooled circulation system can accelerate its operation, thereby achieving the goal of rapid cooling.

Adjusting the working parameters of the water cooling system makes it possible to improve cooling efficiency, save time, and meet process requirements.

3. Therefore, the water circulation system of the vacuum brazing furnace does not require manual intervention, and its operation and shutdown are all automatically complet by a programmable control system

Aluminum Vacuum Brazing Furnace Factory

Vacuum Furnace Control System

- The touchscreen pages are scientifically design, and some pages can be switch between Chinese and English.

- Important parameters and settings are encrypted, and users can set different access permissions for each engineer to ensure the security of device operation.

- When the program is loaded and running, engineers can modify the parameters midway, and the program can continue to run after being corrected, without affecting the already loaded program.

- Any unit that can be controlled, such as temperature adjustment, valve opening and closing, and the operation and shutdown of the vacuum pump, can be visually operated on the touchscreen, and the operation steps can be programmed to implement program instructions.

- It can store 999 different production processes without expansion, including temperature heating, insulation, cooling, alarm setting, vacuum pressure setting, etc.

More vacuum furnaces

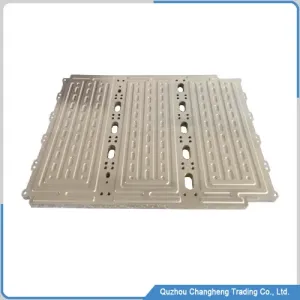

How to produce battery cooling plate

Introduction to cooling plate The battery cooling plate is a key component of EV vehicles, which dynamically adjusts the working temperature of the battery. Due to the high density of batteries nowadays, a large amount of heat is generated during…

Aluminum brazing furnace

Product Description Aluminum brazing furnace is an industrial equipment for high-temperature production, with a maximum design temperature of 750 ℃ and a normal operating temperature of 620-630 ℃. It uses high temperature to melt and cool aluminum materials, thereby achieving…

vacuum hardening furnace of metal

Machine Overview A metal vacuum hardening furnace is a device that utilizes a vacuum environment for metal heat treatment. Heat the metal workpiece under a vacuum to the desired temperature and then rapidly cool it to improve the properties of…

Packaging and shipping

We are responsible for transporting the vacuum furnace to any port in China, as this is a special machine that requires our professional engineers to put it into a container.

Vacuum furnaces in Chinese factories will undergo rigorous testing and then be disassembled. Important parts are all packed in wooden boxes. This wood has been sterilized by high-temperature steaming, and it meets the strict standards of international logistics.

When the vacuum furnace arrives at the buyer’s factory, we can send an engineer to supervise the unloading if necessary. Still, the buyer needs to cover all the expenses for the engineer.

Training and quality assurance

Technical training is divided into two parts. The buyer can send engineers to our factory in China to inspect and accept the machines, and receive simple training on how to install them.

The second part is that we specify a training plan to ensure that the buyer’s engineers can operate the vacuum furnace independently and produce high-quality products.

The training content includes the following.

- The control and operation of a vacuum furnace.

- Customization of production processes and editing of programs.

- An overall introduction of the equipment.

- Response measures for alarm information.

- Daily maintenance and upkeep of equipment.

Our quality assurance meets China’s national standards. The warranty period starts from the date of acceptance of the equipment, and the repair time is 12 months.

If the buyer’s engineer operates improperly, causing mechanical failure, we will also provide necessary help and repair plans.

WECHAT

WECHAT