Instrument Overview

This Temperature Profiling instrument is an important quality management tool in modern industrial production. It can synchronously track temperature data at 10 monitoring points, covering a temperature range of -40° to 1370°. It can accurately capture the temperature changes in complex environments such as industrial furnaces, spray painting industries, and cooking equipment, and record the data throughout the process to display it as a curve.

The tool is equipped with a 1000mAh lithium battery. While recording data, it can also synchronize data to a computer through WIFI transmission technology. Engineers can analyze data in real time and accurately control the heat treatment process, avoiding the impact of data lag on product quality.

Temperature Profiling Instrument Technical Parameter

- Measurement performance: -40~1370℃, ±0.5℃ accuracy.

- Data system: 16MB flash memory, supporting storage of 16 experimental data sets.

- Sample resolution: 0.05-999 seconds sampling interval.

- Sensor configuration: 10-channel K-type thermocouple.

- Power supply management: 3.7V lithium battery power supply, 950mAh capacity, 35mA low power consumption design.

- Charging type: Supports USB-C fast charging.

- Physical characteristics: Military-grade aluminum alloy shell, IP54 protection level, working temperature -20~85℃.

- Communication interface: 802.11n wireless protocol, supports TCP/IP remote access, 2.4GHz/5GHz dual-band.

Temperature Profiling Advantages and Characteristics

- High-quality insulated lunch box

The original three-level protection technology ensures that the internal temperature of the heat insulation box always stays around 70° when the test temperature reaches 1370°, effectively protecting the temperature distribution instrument from malfunctioning in harsh environments.

- Complete data protection

The Temperature Profiling instrument uses multi-channel storage technology, supporting 15 groups of temperature data to be stored independently inside, and can set different parameters for each channel’s acquisition cycle, ensuring the independence and security of each data.

- Industrial-grade measurement accuracy

The temperature error range is ±0.5℃, and the temperature acquisition resolution is 0.1℃. This accuracy range meets the standards of aerospace. It provides reliable data support for the optimization and improvement of production processes.

- Wireless data interaction

The computer can monitor data changes in the built-in WIFI data transmission module in real time. In an emergency, engineers can respond quickly to avoid unnecessary losses.

Temperature Profiling instrument working video

Parts Configuration Checklist

| No. | Part Name | Quantity |

| 1 | Instrument packaging box | 1 PCS |

| 2 | High-temperature tape | 1 PCS |

| 3 | High-temperature gloves | 1 PCS |

| 4 | Thermometer host | 1 PCS |

| 5 | High temperature tape | 1 PCS |

| 6 | Insulation box | 1 PCS |

| 7 | Software USB drive | 1 PCS |

| 8 | Data connection cable | 1 PCS |

| 9 | Thermocouple plug | 10 PCS |

| 10 | Operation manual | 1 PCS |

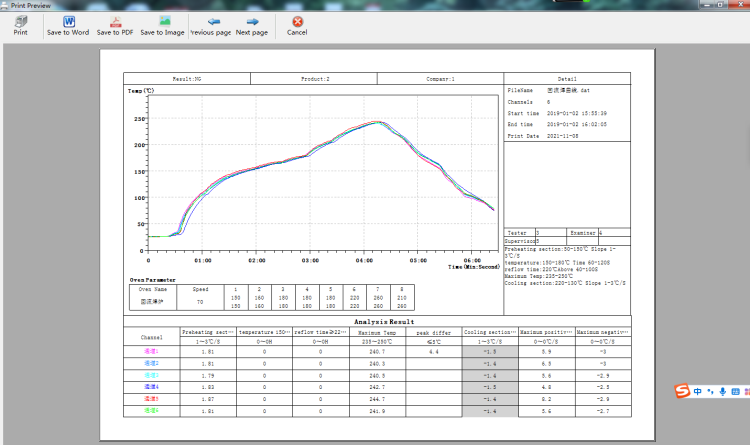

Analyze the features of the software

The software is developed based on the Windows 11 architecture platform and supports multi-language switching. The interface design of the software is reasonable, without annoying ad implantation. The data displayed in each window is simple and easy to understand, without complicated settings and switching.

The Temperature Profiling instrument software has various report templates and can automatically generate temperature curve reports. Users can set up test result reports with just one click based on the data analysis results, and then output them in Word or PDF formats. If your computer has a printer, it can realize one-click printing.

Moreover, the software supports the analysis of historical data, and users can freely switch between multiple windows to compare data and statistics. We promise that the software will be upgraded for free for life, ensuring that users can get the latest algorithm support.

The advanced features of the Temperature Profiling instrument

Intelligent Diagnosis

The control software will monitor the thermocouple data in real time. If there are any data short circuits or abnormalities, the software will automatically trigger an alarm.

Support for mobile Internet of Things

The software of this device is compatible with Windows 11 tablet computers, enabling online data sharing and file printing output.

Multidimensional data analysis

The thermocouple is wrapped in a special metal, which can collect temperature data at any location in three-dimensional space and automatically recognize abnormal temperature changes.

The application scenarios of the Temperature Profiling instrument

- Electronics manufacturing industry.

The automated PBC welding production line adopts a high-temperature continuous production mode, and the melting and cooling of solder paste require a high degree of temperature control. Therefore, to avoid solder defects and component damage, it is usually necessary to use this temperature acquisition instrument to control temperature changes accurately.

- Metal processing and heat treatment.

In the process of annealing and quenching, engineers need to know the temperature in the vacuum furnace and its impact on the chemical changes of metal parts. They also need to grasp the hardness and toughness of the material at each temperature stage, which requires the Temperature Profiling instrument to participate in improving quality and production efficiency.

- Food processing and sterilization.

In the food production industry, it is necessary to sterilize canned foods and dairy products and monitor temperature changes during the sterilization process. This can help ensure food safety and avoid incomplete sterilization due to temperature failure.

This Temperature Profiling is also needed for baking and deep-frying to track the uniformity of temperature and ensure stable food quality.

- Scientific research experimental field

In the aerospace field, the development of new materials and heat treatment, as well as the temperature calibration of high-temperature experimental boxes, all require the participation of this temperature distribution instrument to ensure the reliability of experimental data.

WECHAT

WECHAT