Introduction to cooling plate

The battery cooling plate is a key component of EV vehicles, which dynamically adjusts the working temperature of the battery. Due to the high density of batteries nowadays, a large amount of heat is generated during charging and discharging processes. Therefore, the battery cooling plate plays an important role by circulating liquid through the internal channels of the cooling plate, absorbing the heat generated by the battery, keeping the battery in its optimal state, and providing reliable safety.

It is making of aluminum alloy material, press and forming by a 3000 ton hydraulic press, then cut the excess part, and finally welding at high temperature to form two aluminum plates into a whole. The coolant flows through the channel between the two aluminum plates, efficiently cooling the heat generated by the battery.

With the rapid development of EV vehicles and the high demand in the future energy storage industry, it seems very important to understand how to efficiently produce battery cooling plates. This article mainly discusses brazing type cooling plates, how to efficiently produce cooling plates, as well as material types and manufacturing processes, testing methods, and design requirements.

The material of the battery cooling plate

The most popular material for cooling plates currently is aluminum, which has good thermal conductivity, strong plasticity, and lightweight characteristics, making it the best choice between performance and cost.

Usually, a cooling plate consists of two plates. One is an aluminum plate that is cut to the required shape and size according to the design, while the other requires a hydraulic press to press and form the necessary channels, cut excess parts, and cut the required installation and positioning holes.

The codes for two aluminum plates are different. One plate is made of 3003 and the other is made of 3003/4343, with 4343 accounting for 10% of the total thickness. During the high-temperature brazing process, 4343 will melt, and after cooling, the two aluminum plates will be connected together to form a completed battery cooling plate.

The thickness of aluminum plate will vary depending on the size of the cooling plate. Typically, the thickness of aluminum material is 1.5-2mm, and large-sized cooling plates will use 2mm aluminum plate.

Battery cooling plate manufacturing process

The production process of different types of liquid cooled plates varies. Here, we mainly introduce the production process and technology of brazed liquid cooled plates

Design phase

Engineers need to design the external dimensions, flow channel arrangement, positioning holes, installation holes, water outlet positions, and other details of the liquid cooling plate according to customer requirements. Through hot runner simulation analysis, optimize the layout and resistance of the flow channel

When all designs can meet the requirements of the battery, it can enter the next manufacturing stage

Stamping and Forming

battery cooling plate consists of two aluminum plates, top plate and bottom plate. The bottom plate needs to be press and forming by a 2000 ton precision hydraulic press. In order to improve production efficiency, laser cutting technology can be useing to cut the excess part of the aluminum plate. This not only reduces mold investment, but also improves production efficiency

Laser cutting machines can use graphic programming to cut the desired shape, positioning holes, and mounting holes without the need for any molds,

Flux spraying

The aluminum of 4343 material needs to be spraying with flux, which is a mandatory requirement for brazing process. Every aluminum plate needs to be spraying with flux, otherwise it cannot be welding smoothly

High temperature brazing

This is the most critical process. Two aluminum plates are stack together and heating in a aluminum brazing furnace with controllable atmosphere. After heating, flux will help to melt the welding layer. After cooling, a complete battery cooling plate will be forming. This process is fully automatic, and the brazing process does not require workers to participate. You can check the video to understand the complete process

Leak testing

Every welded cooling plate needs to undergo a leakage test, usually using pressure attenuation method. Compress air enters the interior of the liquid cooling plate through precision testing instruments, and after holding for a period of time, changes in pressure are detected. If there is no change in pressure, it is judged that there is no leakage

OEM factories usually use helium mass spectrometry leak detection methods, which are more precise and can detect extremely small leaks. However, the price of these instruments is generally expensive and ordinary factories cannot afford their price

Cooling plate factory video

Factory machine list

- Hydraulic type stamping machine

- Laser cutting machine

- Flux spraying machine

- Aluminum brazing furnace with controllable atmosphere

- Automated handling machine

- Helium leak testing machine

- Pulse fatigue testing machine

- Thermal performance testing machine

- High pressure blasting testing machine

- Corrosion resistant experimental machine

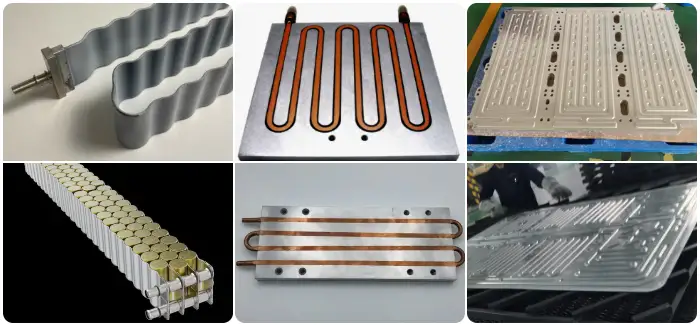

Types of battery cooling plates

There are several different types of solutions for liquid cool plates, which share the common feature of using liquid cooling for efficient cooling, but differ in structure and design

- Copper pipe embedding type

This battery liquid cooling plate is made of an aluminum plate with a thickness of 10mm. The aluminum plate is cut into S-shaped grooves using a CNC machine, and then copper pipes are embedded in the grooves. The medium flows through the copper pipes to remove the heat from the battery

The advantage of this battery cooling plate is that the manufacturing process is simple, the investment amount of the factory is relatively small, but its cooling efficiency is relatively poor, only suitable for scenarios with low heat dissipation requirements, such as lightweight electric vehicles and inefficient energy storage systems

- Micro channel aluminium tube bending type

The round lithium batteries are arranged in order. There is a micro channel aluminium tube in the middle of each row of batteries. It is bent according to the arc of the battery and perfectly matches with the battery to make full use of every space

This type of liquid cooled plate has many advantages, such as low price and the ability to automate efficient production. However, due to various reasons, the application of this type of liquid cooled plate is relatively rare

- Brazing type liquid cooled plate

This type of liquid cooling plate is the most widely useing in high-end cars. It is install at the bottom of the battery and not only has the ability to cool quickly, but also can protect the safety of the battery. Currently, top battery factories in China adopt this design

Producing this type of cooling plate requires a significant investment, and the technical requirements for producing this type of liquid cooling plate are also the highest in the industry. Even so, there are still many people who want to plan to start producing this type of liquid cooling plate

Our best-selling machines

Experimental method of battery cooling plate

Thermal performance testing

The liquid cooled plate simulates actual usage scenarios in the laboratory, with the coolant flowing inside. A heater is installed on the surface of the cooling plate to simulate battery heating. Temperature is collected through thermocouples distributed throughout, and the uniformity of heating and cooling efficiency are calculated using a computer to verify whether the thermal performance meets the design requirements

Pressure pulse durability test

Simulate the driving conditions of a vehicle, with the coolant flowing in high-pressure pulses internally and applying a set pressure and flow rate. Test continuously for several months or a year for 7 * 24 hours to check its fatigue strength, and then check for any leaks

Blasting pressure test

Seal the water outlet, and the pressure testing machine applies internal pressure from the water inlet until the liquid cooling plate bursts, checking its maximum withstand pressure and verifying its safety performance

Corrosion resistance test

Place the battery cooling plate in a high concentration salt spray environment to accelerate the corrosion process and evaluate the corrosion resistance of the material in harsh environments

The Final summary

With the development of industry and the rapid iteration of EV vehicles, due to the highly intelligent interior and powerful power output of battery cars, the intelligent driving of future cars cannot be separated from the power motor. Therefore, the demand for battery cooling plates will increase.

It may seem very simple to weld two aluminum plates together, but it requires materials science, fluid mechanics, precision mold design, high-temperature brazing technology, high-end technical support for each step, and large-scale production factories that require a lot of capital to start. If you want to start producing this cooling plate, you need to go through a professional team’s evaluation before making a decision.

Thank you very much for reading this article. If you need to know more, you can contact our engineers for more details.

WECHAT

WECHAT