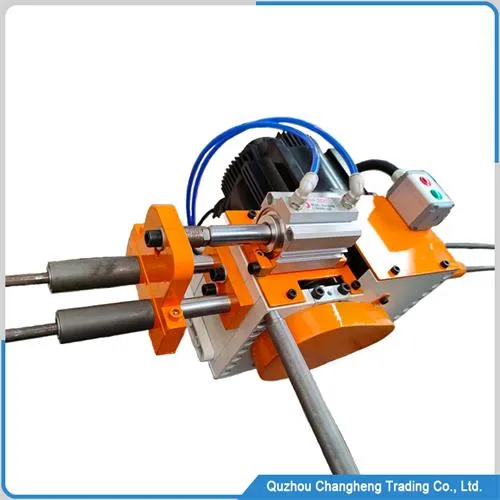

Machine Overview

This is an innovative Tube expanding machine production equipment, whose core function is to drive the metal rod to expand the heat exchanger’s tube through a servo motor, so that the fin and tube of the core can be closely combined, forming a good heat transfer capability, thus achieving higher heat exchange efficiency.

Traditional Expansion machines rely on hydraulic stations to drive the movement of simple mechanical parts, which have problems such as poor accuracy, inability to control the size, and high noise during operation. However, the new Expansion machines are driven by servo motors, which perfectly solves this series of problems.

This Tube expanding machine can not only efficiently produce heat exchangers with a length of 1-2 meters, but also perfectly compatible with heat exchangers of 5-10 meters. Moreover, it can accurately control any length. Taking a 6-meter copper pipe as an example, its error will not exceed 0.1mm.

The layout of the expanding needle adopts a flexible modular design, which supports any layout of 2-12 tubes. Users can adjust this machine’s expanding needle according to the fin’s layout size to meet the production needs of multiple tasks.

Tube expanding machine data

| No. | ITEM | DATA |

| 1 | Drive | servo motor |

| 2 | Workstation | 2-12 optional |

| 3 | Tube diameter | 6-20mm |

| 4 | Tube metal | copper aluminum stainless steel titanium alloy |

| 5 | Pipe wall thickness | 0.1-1mm |

| 6 | Maximum length | 5-10 meters freely controllable |

| 7 | Geometric arrangement | Size customization |

| 8 | Layout method | gantry |

| 9 | Hydraulic station | No need |

| 10 | Appearance craft | baking paint |

Tube expanding machine characteristics

- Powerful and highly compatible.

This machine uses a servo motor to achieve geometrically increasing force through a gearbox. Without worrying about tube rupture and deformation, it can output mighty power to perform stable expansion on materials such as copper, iron, stainless steel, aluminum, and titanium alloys.

- Precise control, efficiency improvement.

The servo motor and the reducer work together precisely to achieve millimeter-level control of the expanding needle, with an error of less than ±0.1mm. Moreover, the maximum speed of the expanding needle is 11 meters per minute. It ensures high-precision control and guarantees faster production efficiency, which is impossible to achieve with traditional hydraulic machine-driven equipment.

- Flexible adaptation, reducing costs, and increasing efficiency.

There’s no need for complex mold changes. For example, if you switch the tube diameter from 15.88mm to 12mm, you only need to replace the expanding ball. The entire mold change time is about 1 minute.

- The human-computer interaction is friendly.

The control system has a 7-inch touchscreen equipped with a multi-language custom touchscreen (supporting English, Russian, Spanish, French, etc.). The operation interface is intuitive, and parameter settings are convenient. It retains physical buttons, such as start, emergency stop, etc.

Tube expanding machine working video

Advanced analysis of the Tube expanding machine

- Intelligent power compensation

We use the PID algorithm to output the servo motor’s torque dynamically. When the device detects that the material is too hard, the system will automatically increase the torque, which helps to expand the tube smoothly.

- Digital control system

This Tube expanding machine was developed based on the requirements of Industry 4.0, and the control panel has reserved multiple I/O interfaces. In the future, it can be connected to the central control system of the factory, realizing scientific management and customized services.

- High-standard surface treatment process

The body of the pipe expander is painted, and the key parts are nickel-plated. These appearance treatments make the equipment look like a work of art, and its appearance will not rust or fade in long-term use.

- Various production modes

The device is equipped with various production modes, such as manual mode, automatic production mode, adjustment mode, maintenance mode, etc. Switching between production modes does not require a complex process and can be completed within one minute. It is as convenient as changing gears in a car.

The application scenarios of the Tube expanding machine

This machine is mainly used in the refrigeration industry. Expanding metal tubes allow them to fit tightly with fins. With the technological advancement in the manufacturing industry, more and more industries are now using this equipment as a productivity tool, such as tube expansion in the new energy industry, tube expansion of tube and shell-type heat exchangers, pipe processing for automotive air conditioners, etc.

Since this Tube expanding machine uses servo motor drive and has a powerful force to expand titanium alloy tubes, CHANGHENG’s tube expansion machines are also widely used in the aerospace field, such as in the hydraulic pipelines of aircraft and the fuel delivery metal tubes of spacecraft etc.

Some special industrial heat exchangers, whose tube length exceeds 10 meters, cannot be manufactured without our Expansion machine.

This device might be your best choice if you also need a machine to expand metal tubes.

You can contact our engineers to get more details about this machine.

Installation and Use

Installation process

Site requirements: According to the uniqueness of your product, prepare a platform or a table. Its size should meet the requirements of your product. The width of the gantry of the machine is 2 meters. Assuming the length of your product is 3 meters, the reserved space for equipment operation should be 6 meters in length and 2 meters in width.

Equipment fixation: The gantry needs to be fixed with ground screws. The balancing device is installed on the gantry.

System connection: According to our Tube expanding machine manual, connect to the Power supply (380V/50Hz) and the gas source (0.4 – 0.8 MPa). For the first startup of this device, you need to make some initialization settings for the servo motor driver. Please read the equipment manual carefully.

Operation steps

Parameter setting: Enter the tube length, the required output for production, and the operation mode through the touchscreen, and the system will automatically calibrate and locate the original position.

Core positioning: Place the heat exchanger core flat on the workbench, check if the core size meets the process requirements, insert the tube, and adjust the spacing of the fins.

Start production: Dilate the metal tube to make it easier for the tube-expanding machine to clamp the tube. Align the metal tube and the expanding needle, press the start button, and the equipment will automatically complete the expanding work, after which the expanding needle will automatically return.

Quality inspection: Expand all the tubes one by one, and then check the appearance and size of the heat exchanger. After each parameter meets the process requirements, proceed to the next cycle to produce another product.

Final summary

With the development and progress of the manufacturing industry, people have put forward higher requirements for producing heat exchangers to achieve high-efficiency output and reduce energy consumption. As the core manufacturing equipment of heat exchangers, the technological innovation of the tube expanding machine directly affects the factory’s competitiveness.

CHANGHENG brand’s expanding equipment, with its servo drive, intelligent precision control, and low energy consumption and noise characteristics, is redefining the production standards of heat exchangers.

WECHAT

WECHAT