Brief introduction

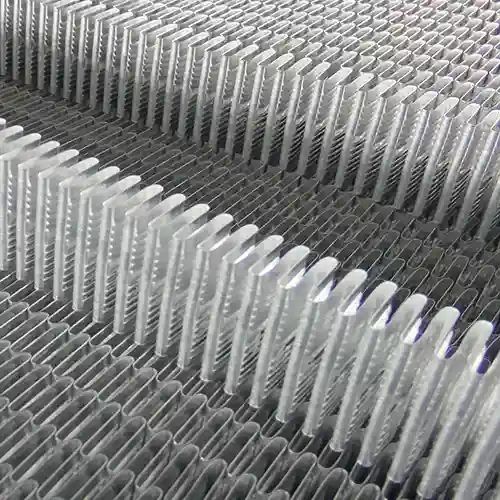

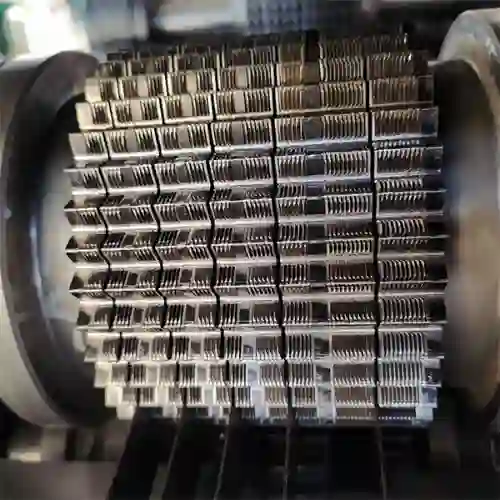

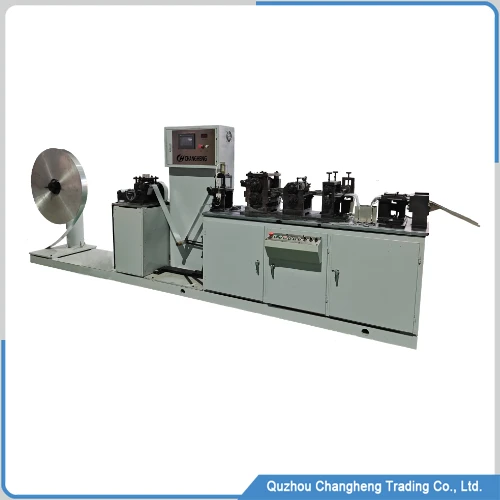

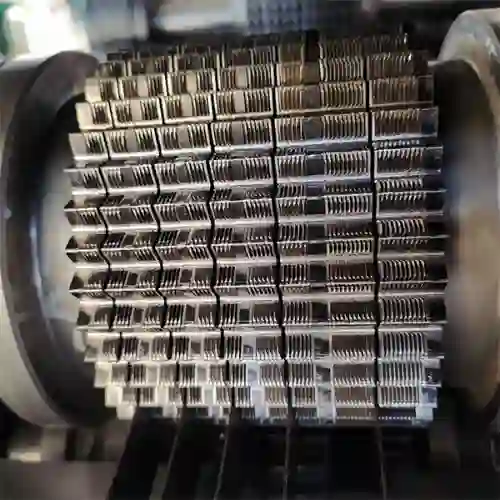

This roller fin machine is a key equipment for processing radiators, condensers, and intercoolers. It has two sets of high-precision rollers, one for rolling louvers and the other for shaping the shape of fins A lubricating oil supply device is installed in the bottom space of the machine, which is fully automatic and provides lubrication for the production of the entire fin.

This fin roller machine is widely used in industries such as automobiles, ships, air conditioning, compressors, engineering machinery, mining machinery, aviation, military, and hydraulic oil cooling. The production of cooling fins in these industries cannot be separated from this machine.

Advantages of Roller Fin Machine

1, Stepless regulation: The production speed can achieve stepless regulation from 0 to 100 meters per minute.

2, Compact structure: The fin roller machine is already equipped with a lubricating oil recovery device, and the lubricating oil tank is installed inside the machine, which does not take up extra space, making the structure more reasonable and the operation very convenient.

3, Efficient production: The main driving motor of this fin machine is 2.2kw, but it can produce a length of 100 meters per minute. Compared to other solutions, this equipment is very efficient.

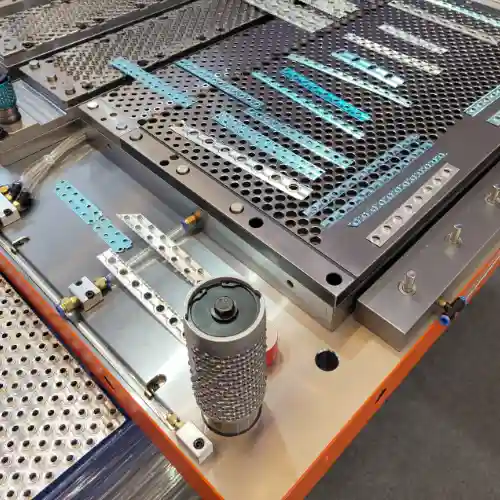

4, Precise control. The cutting part of this roller fin machine is driven by a servo motor, which is used to precisely control the length of each fin and ensure product consistency.

5, Low maintenance cost. Due to the reasonable structural design of the equipment, many parts have undergone precise simplification and a fully automatic lubrication system, which does not require maintenance and upkeep during use.

Roller fin machine details

| No. | ITEM | DATA |

| 1 | Speed adjustment | CVT variable speed |

| 2 | Fin height | 5-12mm |

| 3 | Fin width | 12-168mm |

| 4 | Fin material | aluminum and copper |

| 5 | Machine weight | 1.5T |

| 6 | Lubrication type | automatic |

| 7 | Maximum speed | 80-100m/ min |

Roller fin machine video

FAQ

A: Of course, it can also produce fins for all car condensers, heaters, and evaporators.

A: Usually, this volatile lubricating oil has a transparent color.

A: We customize the power supply for this machine based on your usage environment, with a default power supply of 380V/50Hz.

wechat

wechat