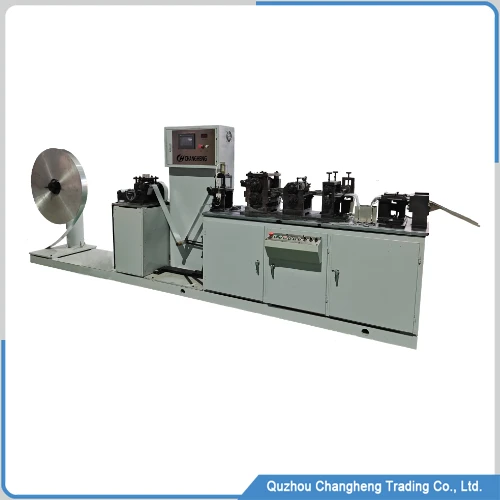

Machine outline

This type of radiator clinching machine is mainly driven by servo motors, allowing engineers to customize programming work steps and achieve automatic obstacle avoidance. The equipment does not require additional molds and can produce trucks and car radiators of any size.

The top of the clinching machine has 6 cylinders for pressing plastic tanks, and 2 sets of robotic arms each for pressing the aluminum core’s head plate. Its fastest production speed is 60-80 radiators per hour

Main features

The radiator clinching machine adopts an advanced touch screen and PLC control to display and set the working status of the equipment. It can store programming data for 999 types of radiators, which means that engineers can freely set programming data for each radiator, which is very helpful for improving work efficiency.

It is particularly suitable for radiators of various vehicle models. For example, truck radiators, engineering vehicle radiators, bus radiators, etc.

This device adopts the famous Taiwanese brand Delta servo motor and servo driver, and the entire device is driven and controlled by the clamping device. It can avoid and move forward according to the shape of the radiator plastic tank.

radiator clinching machine Technical parameters

| No. | ITEM | DATA |

| 1 | Radiator core height | 100cm |

| 2 | Radiator core width | 85cm |

| 3 | core head plate width | 15cm |

| 4 | Step length | adjustable |

| 5 | Total power | 2.5kW |

| 6 | Voltage level | AC220 V/50 Hz |

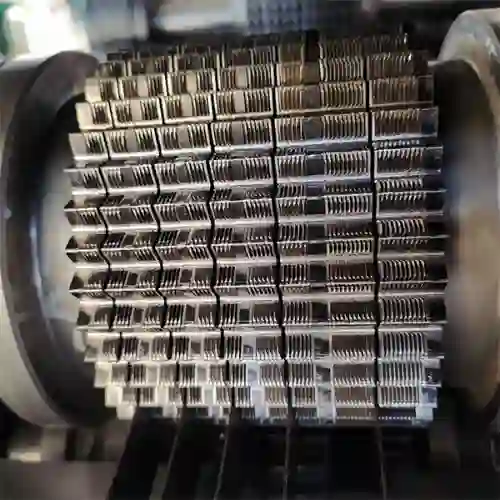

radiator clinching machine Work steps

1, Place the rubber gasket inside the aluminum core head plate of the radiator.

2, Place the plastic tank into the aluminum core and gently press the rubber seal.

3, Install the aluminum core of the radiator, rubber sealing gasket, and plastic tank into the processing position of the machine.

4, Press the start button of the machine, and the machine will start working. Wait for the machine to help press the radiator to complete before taking out the radiator.

5, Using the same steps, install the other side of the radiator and complete the entire radiator. At this point, one radiator is completed

Our success stories

radiator clinching machine working video

FAQ

A: This depends on the size of the radiator of the roller. The maximum working size of this machine is 1000mm. If your radiator is larger than this size, we can customize a larger machine.

A: This job usually takes 1-2 hours.

A: The weight of the latest machine is 1.25 tons.

wechat

wechat