Product Description

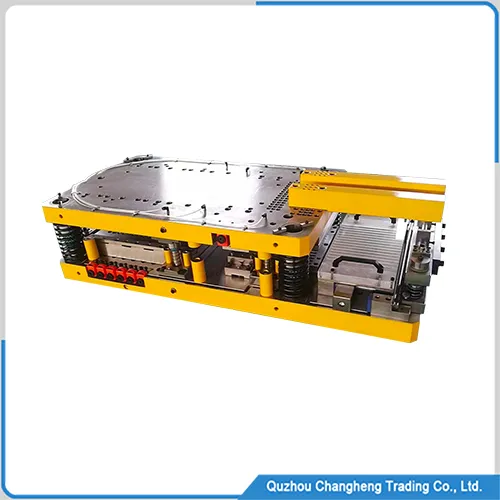

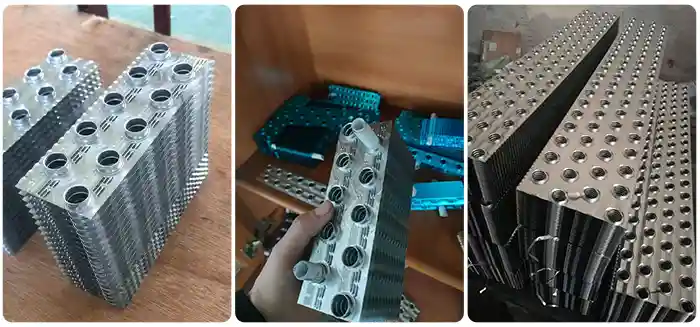

This fin die is a core tool in the HVAC industry, designed to meet the requirements of continuous high-speed production. It mainly produces complex fin products stamped from aluminum, copper, and stainless steel materials. These fins are key parts in refrigeration, heat dissipation, and the HVAC industry. The fin mold’s design directly affects the entire product’s heat exchange efficiency. Therefore, there are various styles of fin shapes, such as louver, wave, sine wave, and elliptical hole types etc.

High-precision machine tools must complete the manufacture of key parts of the fin mold, and each independent unit in the fin mold needs to be closely match; otherwise, it is impossible to guarantee the mold’s stamping speed of 300 times per minute.

The materials of key parts are high-quality steel from Japan and Sweden (SDK51, HAP40), ensuring the wear resistance of the parts. These parts design independently and modularly. When the parts wear out after long-term use, they can be replaced at a very low cost, extending the lifespan and economic benefits of the entire mold.

The advantages of the HVAC fin die

- High-precision manufacturing

The metal materials are made of high-quality steel and manufactured with high precision. The error of key parts is ≤0.002mm, which makes the service life of the mold exceed 400 million presses.

- Multifunctional integration.

A single set of molds integrates multiple steps such as stretching height, cutting edge, punching, and bending, realizing a fully automated production mode.

- Super convenient maintenance.

Key parts are designed independently, which can be replaced quickly. Replacing wear parts or switching models takes less than 15 minutes.

- Flexible adaptability

The fin mold has a regulator with a digital display. Engineers can adjust the pitch size of the fin from 1 to 5mm, and the large mold can achieve an adjustment of 5-15mm.

HVAC fin die Technical Parameters

- Punch life: 120 million times

- Punch material: SDK51

- Assembly accuracy: ±0.03mm

- Hardening: HRC60-62

- Key parts: Modular design

- Collar height: 1-5mm or 5-12mm

- Hole type: round, oval, or olive, optional

- Hole layout: 2521.65mm, 5050mm, and other sizes are available for selection

- Materials: aluminum, copper, stainless steel, etc

- Pitch adjustment: Built-in adjustment module

- Lubrication device: Includes

- Fin Move: Automation

- Cut off: Included

- Fin Edge: Wavy, straight, or curved options available

HVAC fin die manufacturer factory video

Advanced features of the fin mold

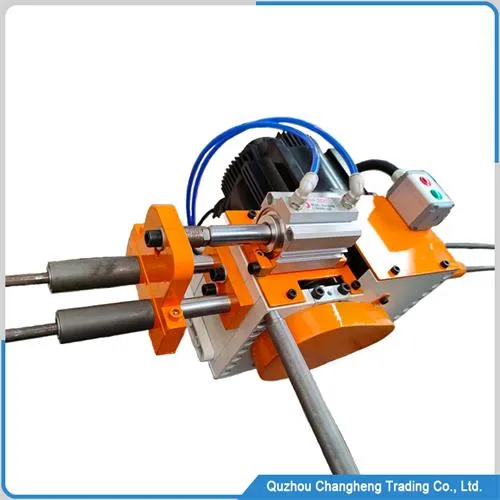

- The guide post of the mold has a lubricant tube, which can be connect to the lubrication system of the stamping machine to achieve unified maintenance and repair, helping to reduce wear and extend the service life.

- With a free geometric layout, users can arrange various sizes according to production needs and produce different sizes of heat exchangers. This process will not generate any additional cost.

- Forced waste discharge: Discharging waste in high-speed production is tough, so the mold must be equipped with vent holes. When the mold is closed, compressed air will open them, forcing waste discharge.

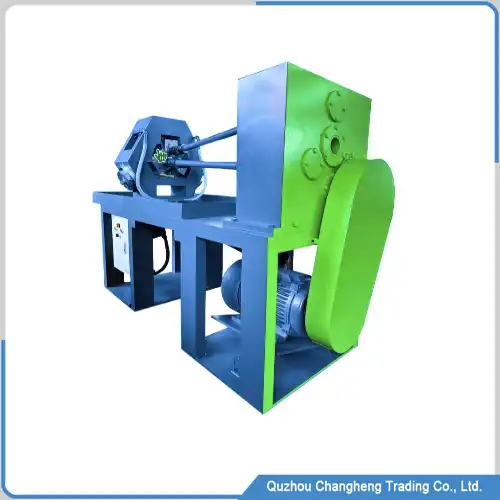

- Built-in mobile slider and the stamping machine are in fully automatic production status, without the need for any worker’s participation. The built-in mobile slider will adapt to the production speed automatically and provide stable feeding of raw materials.

The manufacturing process of the HVAC fin die

Design

Making this fin mold is a complex process. First, engineers will design the mold according to the material and shape of the fin, reasonably distribute each action, and confirm the installation holes and maximum height according to the characteristics of the stamping machine, etc.

Secondly, engineers will draw production drawings for each part used to manufacture each part, and then assemble and debug the molds.

Processing

The processing of parts is divided into several steps. Firstly, the part’s raw material is preliminarily processed, which is usually quickly shaped into the required form.

Secondly, this part will be precisely machined, such as positioning drilling, high-precision grinding, and other processes. Then, some key parts need to be hand-polished and measured.

Hardening

The special parts of the HVAC fin die need to be harden. The vacuum quenching technology can make the hardness of the parts reach HRC60-62, improving the toughness and wear resistance of the parts.

This process can ensure the parts’ size and increase the molds’ lifespan. Some parts need to be polish after quenching to improve their precision further.

Assemble

The final assembly mold requires skilled engineers to complete. Some minor burrs need to be Hand polishing, and small defects need to be correct immediately. The installation of the guide pillar requires an interference fit.

Before testing, we need to repeatedly check each part’s fitting relationship and quality to ensure no mistakes after the mold is assemble.

The application of HVAC fin dies

- Industrial refrigeration

We need large heat exchangers and condensers in the shipbuilding and refrigeration industries. This mold is one of the key molds for producing such products.

- HVAC industry

The cooling fins of products such as central air conditioners and dehumidifiers in the commercial and civilian sectors require specialized molds for manufacturing.

- Green energy industry

Large-scale solar power generation requires tube-type heat exchangers for energy exchange. The tubes of these heat exchangers have many fins produced by this fin mold.

FAQ

A: Of course, it can produce copper materials.

A: The warranty period for the mold is one year or 100 million presses.

A: We can design this fin mold based on your existing stamping machine.

A: When you purchase molds, we will provide free fin samples. We will pack these samples using a dedicated packing machine to ensure they are protected from damage during transportation.

WECHAT

WECHAT