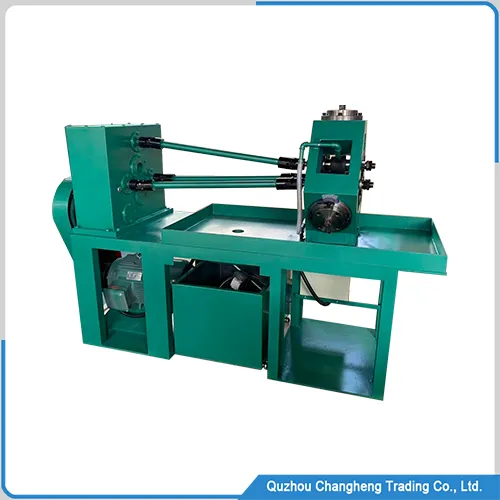

Equipment Overview

This Evaporator fin machine for producing fin of automobile evaporators. It is composed of automatic feeding of raw materials, continuous forming of fin, automatic precise cutting and other parts. It uses an intelligent control system, and the production process of fin is fully automatic.

This machine is equipped with a 7.5kW motor, and the maximum speed is 1440 revolutions per minute. The output of torque is expanded through 1:10 pulley conversion. The main shaft has rotated 144 times per minute at high speed, driving the cam to achieve piston type high-speed production of fin.

The driver of the motor is a Mitsubishi brand, which can flexibly control the rotation speed of the motor, achieving a stepless speed change capability of 0-144 times per minute. Changing the production speed does not require a complex gear shifting process, and engineers only need to rotate the control button to easily change the production speed.

Technical data of evaporator fin machine

- Metal materials: stainless steel, aluminum, copper

- Foil thickness: 0.05-0.5mm

- Fin pitch: 0.5-10mm

- Fin height: 1-12mm

- Fin width: 0-300mm

- Production speed: 0-144 times/minute

- Feeding machine: including

- Lubrication device: built-in

- Fin mold: replaceable

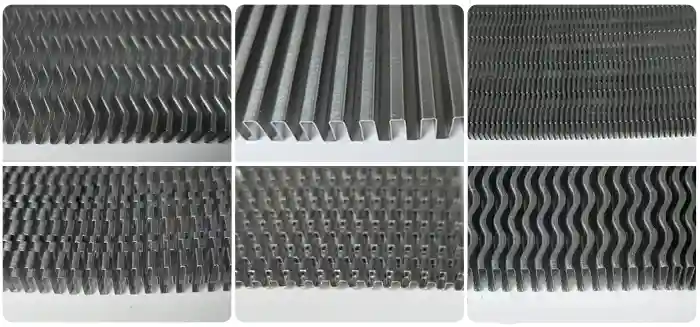

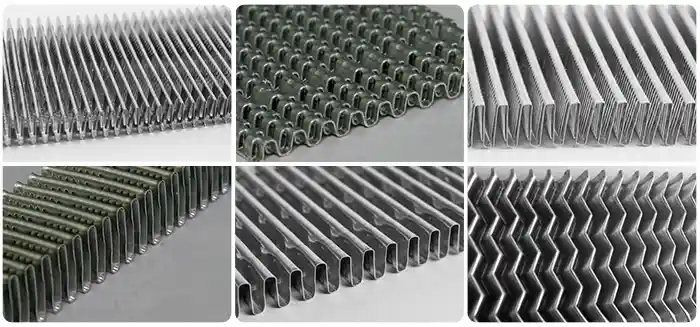

- Fin shape: wave, Sawtooth, straight, etc

Working video of evaporator fin machine

Advantages of evaporator fin machine

No raw material testing

During the production process, if the metal material is uses up or broken, the detection sensor will capture a signal in milliseconds and send it to the PLC to automatically stop running and issue a warning.

Built in lubrication device

Metal materials require volatile oil lubrication during the production process. This fin machine have a built-in lubrication device and operates fully automatically without manual intervention. There are sensors in the oil tank that issue warnings when the lubricating oil is running out, preventing the machine from running out of oil and causing malfunctions.

Design of replaceable molds

Because there are many models of automobile evaporators, one size of fin can not meet all the needs of the market, so this machine adopts flexible mold design, which greatly reduces the use cost of users. By replacing fin molds with different shapes, it can meet the diversified market needs.

High precision manufacturing technology

Large fin dimensional tolerance will directly affect the quality of the evaporator, and the brazing process will lead to the leakage of the evaporator, resulting in irreparable losses, which puts forward high requirements for the manufacturing of fin molds. Therefore, the parts of fin molds must be making with high precision, so that the size error range is controlled at the micron level.

Precision cutting device

The Evaporator fin machine cutting device uses a servo motor to drive the gear to rotate, and each tooth of the gear can only move one fin pitch, so that its length can be calculated from the fin pitch, and accurate cutting can be achieved. Generally, its cutting length error is 0 mm.

Other types of fin machine

Fin roller machine of radiator and condenser

Machine Outline The radiator fin roller machine is the core equipment for processing condensers, radiators, and intercoolers. Its total power is 3.5 kW, demonstrating strong power. More importantly, the fin drum mold’s exceptionally high manufacturing…

Fin stamping machine of condenser and heat exchanger

Machine outline This high-speed fin stamping machine is an ideal fin production equipment, widely used in the automotive, household appliances, and industrial heat exchanger industries, The working principle of this machine is to achieve high-speed…

Fin making machine for industrial production

Machine outline This is a metal fin making machine, which can produce fin of different metals such as copper, aluminum, stainless steel, titanium alloy, etc. The machine has a very wide range of applications, such…

Fin tube machine | finning machine manufacturer

Product Description The metal fin tube machine is an upgraded third-generation equipment that can roll single and bimetal finned tubes made of steel, steel aluminum, pure aluminum, copper aluminum, and other metals. It operates smoothly,…

Evaporator fin machine feeder

This machine is an independent operating device with two feeding control sensors. When the metal material contacts the bottom sensor, it will stop feeding, and when the metal material contacts the top sensor, it will automatically feed. In addition, it also has a no material detection sensor. If the machine runs out of material, it will immediately stop to prevent the machine from running out of material.

This machine can install materials with an inner diameter of 152mm. A tool for installing the expansion wheel can be compatible with raw materials with an inner diameter of 300mm. If your raw material has an inner diameter of 450mm, please let us know. We have a Evaporator fin machine that can use 450mm raw materials.

This feeding machine can install metal materials with a maximum outer diameter of 1000mm and a maximum width of 450mm. If your material is larger than this size, you need to notify us and we will customize a larger feeding machine for you.

If your fin machine needs multiple channels for simultaneous production, we also have a multi-channel feeder to meet your needs, but it is a customized equipment. You need to provide the width, inner diameter, outer diameter and other parameters of your Id raw materials.

Final summary

This evaporator fin machine is one of the most popular fin production machines at present. It is not only uses in the field of automobile evaporators, such as plate and bar heat exchangers, household electric heaters, generator coolers, battery car oil coolers and other fields.

This ChangHeng brand fin machine not only realizes high-precision manufacturing of fin, but also realizes diversified production through low-cost mold replacement to meet the production needs of different industrial fields. Not only that, but also the production of multiple metal materials is one of its advantages.

If you are really looking for a high-speed fin machine to produce evaporator, condenser, radiator and other industrial products, then this fin machine is one of the best choices. It is not only widely used, easy to change mold, high-precision size output, but also very competitive in price. What are you waiting for? Contact our engineers for more details about this machine.

WECHAT

WECHAT