Machine Overview

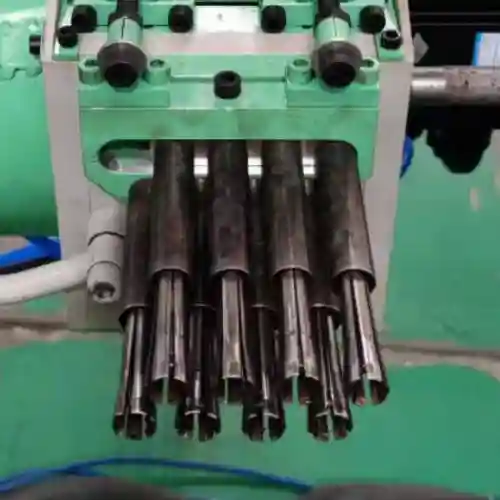

This copper tube expander is driven by a servo motor and uses a 1:10 gear to increase power output. It can expand 2-12 metal tube at a time. It is very suitable for the production of large industrial heat exchangers.

The machine adopts intelligent control, which can accurately control the required length size, with a maximum error of no more than 0.1mm, perfectly solving the defect of traditional hydraulic expansion machine copper pipes being punctured.

In addition, metal tube with different diameters can be expanded by replacing the expansion ball, which is a very good design for factories that need multi size production requirements.

In addition, this tube expander has enough power to expand copper, aluminum, iron, stainless steel, titanium alloy and other metals. If your heat exchanger tube are made of these materials, this machine is your best choice.

Copper tube expander machine Technical Parameter

| No. | ITEM | DATA |

| 1 | Expansion | 2-8pcs |

| 2 | Drive type | servo motor |

| 3 | Pipe diameter | customized |

| 4 | Motor voltage | 7.5kw |

| 5 | Tube wall thickness | arbitrary |

| 6 | Power supply | 380V/ 50Hz |

| 7 | Geometric Arrangement | Follow Design |

| 8 | appearance | gray white |

| 9 | Language | Chinese & English |

Advantages of the Copper tube expander machine

This tube expansion machine is a device that has undergone multiple design improvements. It uses a servo motor as the main driving force to ensure powerful driving force while also accurately expanding the length

Its advantages include the following

Powerful power

This machine uses a 7.5kw servo motor to drive a 10 times variable speed gearbox, which outputs powerful power. It can almost expand heat exchanger tubes made of various metals, such as copper, aluminum, stainless steel, titanium alloy, etc

Flexible geometric layout

Thanks to its excellent design, this expansion device can adapt to almost any type of complex heat exchanger. One machine can handle multiple geometric layouts of different sizes, and it only needs to replace a simple tool to achieve it easily

Precise control

The machine adopts PLC as the main control, with multiple working modes to choose from, and allows engineers to set the expansion length through the touch screen, with a maximum error of no more than 1mm,

Balance device

We have installed the most advanced balancing device for the expansion machine, so workers will not feel tired even after working for a long time

Other type of heat exchanger machines

Tube expanding machine for heat exchanger

Machine Overview This is an innovative Tube expanding machine production equipment, whose core function is to drive the metal rod to expand the heat exchanger’s tube through a servo motor, so that the fin and…

Vertical expander machine of heat exchanger

Machine contour The vertical expander machine is a key equipment in the heat exchanger industry. It adopts a vertical design layout. The expansion needle expands all hairpin tubes from the mountain to the bottom at…

Automatic copper tube cutting machine of heat exchenger

Product Description The HVAC industry uses an automatic copper Tube cutting machine, which consists of a copper pipe frame, straightening device, chip-free cutting, and other parts. This device has multiple workstations, each of which can…

Fin press machine of heat exchanger

Machine Overview This fin press machine is specialized equipment for high-speed stamping processing, which is usually used in manufacturing industries such as automobiles, household appliances, and hardware products. This type of machine has high speed…

Copper tube expander machine working video

Which fields use copper tube expander machine

This machine has powerful power output and intelligent control. The maximum length of the expansion rod is 10 meters, so it is very suitable for producing large industrial heat exchangers.

Usually, if the length of the heat exchanger is greater than 6 meters, other types of expansion machines cannot meet their production needs and must use this convenient expansion method for production.

This machine is also compatible with producing small heat exchangers, but its production efficiency can be slower. Due to its low price, some small heat exchanger factories also use this machine as their main production tool.

In some shell tube heat exchanger industries, they need stainless steel or titanium alloy metal tubes. These tube need strong force to be expanded, so this expansion machine has played a role.

WECHAT

WECHAT