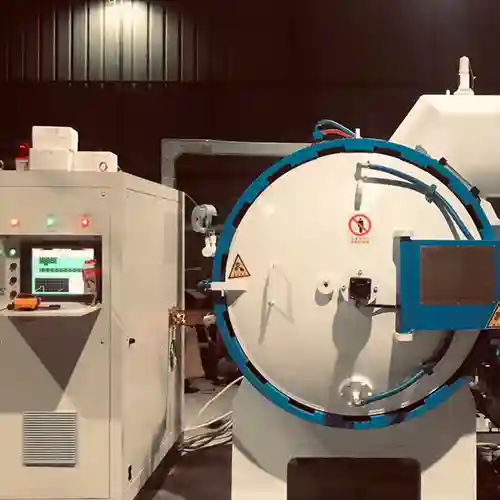

Machine overview

This is due to the vacuum annealing furnace that relieves metal stress. Its maximum design temperature is 1200 °C, which is uses for the annealing heat treatment of industrial parts or rare metals.

The furnace uses multiple sets of heating zones to control temperature changes, with a maximum accuracy of 1 °C, which can meet the annealing process of all metals in modern industry and other heat treatment processes

The vacuum furnace uses molybdenum metal as the heating element. There are insulating ceramics and multi-layer stainless steel reflection screens in the middle of the heating parts and the furnace body, which fully isolates the temperature and does not spill over. This design not only keeps the furnace body temperature below 30 °C, but also effectively reduces heating energy consumption

Annealing Process of Vacuum annealing Furnace

- Place the metal parts that need to be heat treatment in a dedicated frame, and then place them smoothly in the furnace using an electric forklift outside the furnace

- After checking that the frame is place smoothly, close the furnace door and lock the furnace door

- Write the annealing process flow. If you have saved this program before, you can select it and start running the vacuum furnace.

- The vacuum furnace is fully automatic during the annealing process. Some special parts need to be annealing multiple times. It will all operate according to the steps set by the program without manual participation

- When the annealing process It’s over, the vacuum furnace will automatically cool down, and then the parts can be take out of the vacuum furnace.

- The metal parts are naturally cooled to ambient temperature in a specific location, and the annealing process is completed here

Technical parameters of vacuum annealing furnace

- Cavity size: 700 * 700 * 900mm

- Heating area: 6 pcs

- Maximum load: 1500kg

- Temperature rise rate: 0~ 25 ℃/min

- Annealing process: programmable

- Maximum vacuum pressure: ≤ 4 × 10-3

- Appearance color: Default is off-white

- Maximum temperature: 1200 ℃

- Insulation material: stainless steel reflective screen

- Heating connection: Insulated ceramic

- Cooling method: continuous water cooling

- Operation mode: programmable automatic operation

- Seals: EPDM

- Furnace door: single door

- Furnace type: horizontal

- Touch screen: 10.1 inches

- Electronic control parts brand: Mitsubishi

- Vacuum pump brand: from China

The technical parameters of each vacuum furnace are different. The parameters of the vacuum furnace you need may be different from it, so these parameters are for reference only.

The advantages of vacuum annealing furnace

Famous parts brand

The control system is made of parts from well-known international brands, such as Mitsubishi or Siemens, as well as some parts from famous Chinese brands, Chint, Delta, etc. High-quality parts contribute to its service life

Programmable process flow

This vacuum furnace has a 10.1-inch touch screen. Engineers can preset complex process flows through the touch screen, whether it is temperature, vacuum pressure, cooling water flow, or vacuum pump control. It can be preset and program through the touch screen, and then it will run fully automatically according to this program

Multi-zone heating control

This vacuum annealing furnace has 6 heating zones, each heater is independently temperature control, which not only effectively improves the uniformity of temperature, but also sets different temperatures for each zone according to different metal products to improve production efficiency and product quality

safety control system

In the normal heat treatment process, whether the vacuum pump is overload or the cooling water is missing, as well as other problems, it will issue an alarm, and the touch screen will display the fault code. Engineers can easily solve the problem according to the fault code

Vacuum annealing furnace factory video

Structural Design of vacuum annealing furnace body

This furnace body is a circular horizontal structure with a single door design. The furnace body and the furnace door are welded with double-layer metal plates. The inner wall is made of 304 stainless steel and the outer wall is Q235 carbon steel. After the furnace body is welded, there will be a stress-relieving process. Then it undergoes a high-pressure sealing test to ensure the sealing performance of the furnace body

The inner wall of the furnace body will be carefully polished and polished to ensure a low degreasing rate in a vacuum state. The outer wall of the furnace body is painted with multiple layers, each of which is coated with anti-corrosion, anti-rust coating and color coating

The furnace door locking method is pneumatic. For safety, the furnace door cannot be opened manually in the automatic operation mode. In the manual mode, the furnace door can be opened one piece at a time, which is very easy.

There are four support feet under the furnace body, which are directly welded to the bottom of the furnace body, and the support rod in the furnace is connected to it. This design can greatly improve the load-bearing capacity of the vacuum furnace.

Vacuum annealing furnace charging system

The function of this inflation system is to transport gas during heating and holding, as well as inert gas during cooling. It consists of an automatic inflation valve, a shut-off valve, a pressure sensor, a pressure gauge, and a flow meter.

Automatic valves can automatically perform gas delivery, valve closing, pressure adjustment, etc. according to the preset process flow, and we also install manual control valves for manual operation under special circumstances to achieve rapid cooling or other technical processes

There is a bleed valve and muffler at the end of the gas transportation pipeline. When the process is completed, the bleed valve will automatically open, allowing the pressure in the furnace to return to normal atmospheric pressure, and smoothly and smoothly open the vacuum annealing furnace door to remove metal parts

The pressure of the inert gas may vary with the capacity inside the pipe. In order to solve the problem of unstable gas pressure, there is a pressure balance valve in the middle of the gas delivery pipeline. With it, the gas pressure delivered to the furnace is effectively control, making the heat treatment process more stable

Why Choose Our Vacuum annealing Furnace?

Powerful intelligent programmable control system, it can freely control parameters such as temperature, control pressure, gas delivery, cooling water temperature management, alarm, etc., and the touch screen supports multiple languages. It can also store 999 different heat treatment processes. Built-in multi-level rights management allows different engineers to edit, save, delete, and other operations on data

Using low-voltage and high-current heating methods, the temperature of multiple heating zones is independently control,

and N-type thermocouples can perform multiple tasks, such as temperature control and recording, over-temperature alarm and heat radiation data collection. This thermal management system not only greatly improves the temperature uniformity, but also efficiently manages the safety of high temperatures

We have a wealth of experience to meet customers’ needs for annealing vacuum furnace working dimensions, heat treatment processes, technical training, installation and commissioning, etc.,

All of which provide satisfactory service in one stop. Not only that, but our prices also have absolute advantages

If you are looking for a vacuum furnace to meet your production needs, you can contact our engineers and you will definitely get satisfactory results

WECHAT

WECHAT