Product Overview

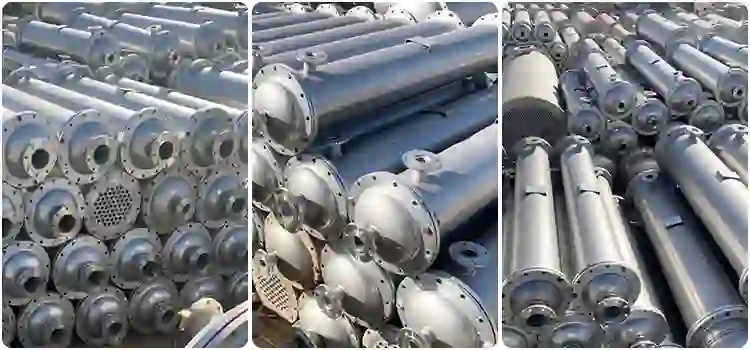

This industrial heat exchanger is key equipment in energy, pharmaceuticals, chemical engineering, and food industries. With its efficient and stable characteristics, this tube and shell-type heat exchanger takes on the task of heat transfer and conversion. In high-pressure applications, this heat exchanger is indispensable.

It comprises components such as a shell, heat exchange tubes, fins, a sealing lid, a tube plate, and a flange interface. Among these, the tube is a special part. To increase the heat exchange area and improve efficiency, the surface of the tube usually has some threads. When the medium comes into contact with the tube, it will generate a vortex, thereby improving the heat exchange efficiency.

The working principle of this industrial heat exchanger is the indirect exchange between two fluids. The corrosiveness of the fluid medium is different, so the metals used will be different, usually carbon steel, stainless steel, hastelloy metal, titanium alloy, etc. Improving the heat exchanger’s lifespan in a highly corrosive environment is also possible.

Characteristics of Industrial Heat Exchangers

Longer lifespan.

The core parts are made of corrosion-resistant metal materials, and their lifespan can reach 10-15 years, or even longer.

Reasonable structural design.

The shell and the lid are designed separately, and users can open the lid at any time to clean the impurities and dirt inside, ensuring the continuous and stable heat exchange efficiency.

Adapt to extreme working conditions.

This industrial heat exchanger can work normally under extreme temperatures, with a maximum temperature range of -50° to 600°, and a maximum pressure resistance of 39.8MPa.

High heat transfer efficiency.

The tube layout adopts a triangular arrangement design, and the circular U-shaped tubes are evenly Distribution, allowing fluid and tubes to fully contact, forming a unique path to improve heat transfer efficiency.

Industrial heat exchanger data

| No. | ITEM | DATA |

| 1 | Material | Stainless steel Carbon steel Optional |

| 2 | Service life | 10-15 years |

| 3 | Internal pipe size | Customized |

| 4 | Fluid | Water, oil, other |

| 5 | Pipe Layout | Follow Design |

| 6 | Outer diameter | Follow the design |

| 7 | Certificate | CE |

The manufacturing process of an Industrial heat exchanger

- Pre-treatment of materials

According to the technical requirements of the heat exchanger design, such as the efficiency of the heat exchanger, the temperature of the outlet, the size of the shell, the size of the tube, and other technical indicators, we pre-process the materials.

- Part molding

Each part is made independently. The shell needs to be laser cut, and the flange and water pipe are welded after being polished smooth. Then, it is polished and surface-coated.

The tube sheet needs to be flattened and drilled using a CNC machine, and the size error of each hole cannot exceed 0.1mm.

- Assemble this industrial heat exchanger

The assembly process is a crucial technique that requires skilled engineers to complete. The installation of tubes and plates requires hydraulic tube expansion technology. In this process, there must be no ruptures, and the contact points between the tubes and plates must be seal by argon arc welding. Otherwise, leakage may occur.

- Pressure test

When the heat exchanger is assembled, it must be pressure-tested by professional machines. The test pressure is 1.5-2 times the normal use pressure, and the holding time is 30 -60 minutes. If the pressure test is qualified, it can be delivered.

The application scenarios of industrial heat exchangers.

- Chemical industry.

In fluid production, such as refrigerants, liquid fire extinguishers, laundry detergents, etc., they need heating, cooling, and distillation processes. The tube and shell heat exchanger plays an essential role in this process.

- Food processing industry.

Dairy products and beer need to be sterilized at high temperatures during the fermentation process, and this process requires the participation of a heat exchanger to meet food safety standards.

- Energy industry.

In the waste heat recovery system of a thermal power plant, it is necessary to convert the heat of flue gas into steam. Using our industrial heat exchanger, the heat exchange efficiency can reach more than 85%.

- Other industries.

With the development of industry and people’s increasing focus on environmental protection, more and more industries are using heat exchangers to reduce energy consumption. In the future, there will be more and more application scenarios for heat exchangers.

Our strengths

All parts are produced independently.

From raw materials to assembly testing, the whole process is completed in our factory, in conjunction with CNC machine tools and welding robots, to ensure that delivery time will not be delayed.

Customized services.

You need to improve the technical parameters or the 2D design, and we will provide a 3D model to confirm the appearance and size of the industrial heat exchanger, and complete the delivery based on the 3D model.

Strict quality control.

Each heat exchanger will undergo a 100% sealing test before leaving the factory, and the inside of the pipeline will be View with a tiny camera to ensure the product’s pass rate.

Certificate support.

Our heat exchanger meets the CE standard of the European Union. We also have other pressure certificates to ensure you can smoothly go through customs and install and use them.

FAQ

A: Neutral plywood or wooden box packaging, according to the customer’s requirements.

A: We will provide the drawing after you pay or prepay.

A: Yes, we can. Most products can be customized, including the Logo on products.

A: Normally, 30 days after payment, and we promise to deliver as soon as possible.

WECHAT

WECHAT