Machine Overview

This heat exchanger expander machine adopts a convenient type design, which uses an electric balancer to hang on the gantry frame. Workers can easily use this machine for expansion work. Moreover, the gantry frame width of the equipment is 2000mm, which is perfectly compatible with all sizes of heat exchangers, and there is no complicated mold exchange and debugging. 95% of the parameter settings are complete through the touch screen

This expansion equipment is equipped with a 3.5kw servo motor, which can output powerful power through three sets of gears to transform torque, and easily expand tube of stainless steel, titanium alloy and other metals. This design perfectly solves the expansion problem of stainless steel and titanium alloy tube in the heat exchanger industry

Because the hydraulic station is cancelled, the noise of the machine during operation is greatly reduced. Moreover, because of the particularity of the servo motor, it can precisely control the size of the metal rod movement, without fear that it will puncture the U-shaped tube

Advantages of heat exchanger expander machine

Flexible tube layout

Since we produce about 100 sets of this machine every year to solve the expansion problem of heat exchangers for customers around the world, we have developed many different types of tube layouts to meet the diversified requirements of customers. Whether your pipes are round or oval, we can provide perfect solutions

It has strong power

This machine uses a 3.5kw servo motor as the main power. Its maximum speed per minute is 3500 revolutions. There are three groups of 1:10 gear conversion to increase torque output. Even if your tube are made of stainless steel and titanium alloy, this machine can easily expand these tube

Intelligent control system

This Heat exchanger expander machine adopts the most advanced PLC and touch screen for human-machine interaction. These parts are from internationally renowned brands. Our power engineers have developed an intelligent control system, and users only need to input the required numbers on the touch screen. This machine can achieve production statistics, torque output control, precise size control, production mode conversion and other functions

Low consumption and silent production

Compared to traditional expansion machines, the motor of the hydraulic station runs for a long time, producing noise greater than 80 decibels and consuming a lot of electricity. To solve this problem, this expansion equipment eliminates the hydraulic station and uses servo motors with intelligent control, allowing the motor to run indirectly. This not only significantly reduces the energy consumption of the machine, but also effectively controls the noise of the machine

Technical parameters of heat exchanger expander

- Production speed: The speed can vary

- Parameter adjustment: Touch screen input

- Power supply: Depending on your country

- Total voltage: 3.5kW

- Compressed air: 0.4-0.6Mpa

- Maximum length: 6 meters,

- Quantity of tube: 2-20, customizable

- Servo motor: Mitsubishi

- Cylinder: Schneider

- Instruction manual type: PDF

- Manual tools: including

- Tube material: copper, aluminum, stainless steel, titanium alloy

Working video of heat exchanger expansion machine

Other heat exchanger machines

Tube bending machine for heat exchangers

Machine Overview In the heat exchanger manufacturing industry, many U-shaped hairpin tubes are needed. Traditional U-tube bending machines rely on hydraulic stations for drive, which consume a lot of energy and generate a lot of…

Water pressure Tube expanding machine

Machine Overview The water pressure Tube expanding machine is special equipment useing in the heat exchanger industry. It consists of a control system, a pressurization system, and special tools for pipes. The water pressure expansion…

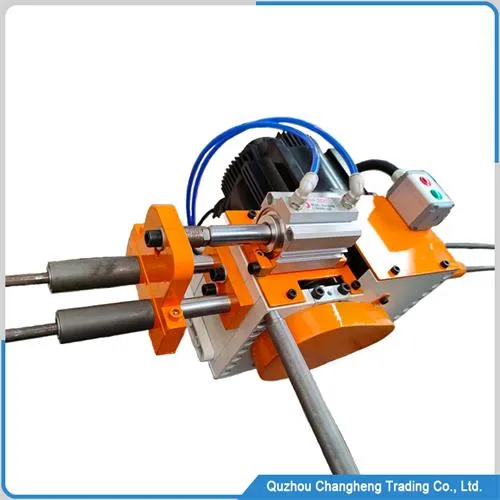

Convenient Portable tube expander

Machine contour A servo motor drives this portable tube expander, easily expanding pipes into various required sizes. Its easy-to-use touchscreen interface makes it convenient for users to operate and set up. This portable expansion machine…

Vertical expander machine of heat exchanger

Machine contour The vertical expander machine is a key equipment in the heat exchanger industry. It adopts a vertical design layout. The expansion needle expands all hairpin tubes from the mountain to the bottom at…

Advanced functions of heat exchanger expansion machine

The body of this expansion machine is made of aluminum alloy material and has undergone anodic hardening treatment, greatly reducing the weight of the body. Workers will not feel tired after working for a long time.

The metal ball of the expansion machine is a key part. It is made of tungsten steel. After vacuum high temperature quenching and hardening, the surface finish of the metal ball has reached the mirror level. The metal ball itself will not be worn, nor will it cause scratches and cracks to tube after long-term use.

The surface of the control cabinet and other parts is painted with baking paint technology, and users can customize its color, but its default color is gray white, which is a color that everyone in modern factories is willing to accept.

The control system of this Heat exchanger expander machine has reserved multiple IO interfaces, which can perfectly meet the production needs of Industry 4.0, allow users to link the machine to the factory’s Internet, and realize intelligent production management.

WECHAT

WECHAT