Machine Overview

This is an aluminum core assembly equipment for plate and bar heat exchangers. It uses multiple servo motors to control and easily set the working size of the machine to meet the production needs of different sizes of heat exchangers. Moreover, during the production of aluminum cores, the servo motors of this equipment are in a stopped state, so it consumes almost no electricity. This energy saving design can improve the economic efficiency of the factory.

The maximum size of this device is 2000mm in length, 350mm in width, and 150mm in height. This working size can meet 80% of the heat exchanger needs in the market, and it can be compatible with any size downwards. Switching between different sizes to produce other heat exchanger models can be completed in just a few minutes.

The frame of this core assembly equipment is made of high-strength steel, and multiple parts are welded using modern welding technology. Then, CNC machining is used to accurately position the dimensions, ensuring that the fit error of each part does not exceed 0.01mm. The top of this equipment has multiple pneumatic hydraulic cylinders. When the aluminum core is assembled, the hydraulic cylinders can ensure the compression of the aluminum core, ensuring good quality and tightness of the aluminum core assembly.

Core assembly equipment Technical parameter

- Assembly type: Plate and Bar Heat Exchanger

- Maximum width: 350mm

- Maximum length: 2000mm

- Maximum height: 1500mm

- Other sizes: Customization accepted

- Drive type: servo motor

- Appearance colors: gray and orange

- Size setting: Free control

- Production type: manual

- Required workers: 1 worker

- Model change time: approximately 5-10 minutes

- Number of cylinders: 3

- Power supply: 220V / 50Hz

- Voltage: 2.5kW

Core assembly equipment working video

Advantages of the core assembly equipment

- Can produce aluminum cores of any size

This machine adopts a unique design and utilizes the precise control characteristics of servo motors. Workers can replace different aluminum core models within 5-10 minutes. This high-efficiency setting is very suitable for factories with small batch production

- High precision manufacturing technology

This board and bar heat exchanger aluminum core assembly machine adopts high-precision manufacturing technology. Whether you are assembling oil cooled heat exchangers or air heat exchangers, the error of the aluminum core will not exceed 0.01mm

- There will be no noise during production

The servo motor of this core assembly equipment only participates in the adjustment and setting work, so during the assembly of the aluminum core by workers, this machine will not produce any noise, nor will it emit any exhaust gas. This equipment is very friendly to the working environment

- Simple control system

This machine adopts the traditional physical button control method, with arrows marked on each button. Even if new workers only need a few minutes of training, they can easily use this machine, which will greatly reduce training costs

Usage and production

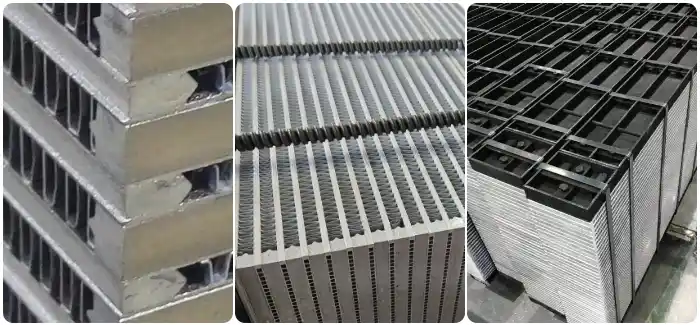

The main function of this core assembly equipment is to produce plate and bar type heat exchangers. The required work space is set according to the size of the product. Workers manually assemble the parts of the heat exchanger like building blocks. When the aluminum core is assembled, the top pneumatic hydraulic cylinder will press down and compress the entire aluminum core. Engineers use metal straps to bind it, and then perform aluminum brazing on the aluminum core

With the development of industry, there is an extrusion type of micro channel aluminium tube. This aluminium tube is very suitable for the production of air heat exchanger. It can not only reduce the weight of the heat exchanger, reduce the material cost, but also not worry about the leakage of aluminum brazing. Therefore, more and more heat exchanger factories use this aluminium tube. Our machine is perfectly compatible with this tube. It can assemble this type of heat exchanger aluminum core without any modification core assembly equipment

FAQ

A: Yes, this machine is perfectly compatible with it

A: If it is a standard size machine, its delivery time is 21-30 days

A: We can provide you with suppliers from China, and you can buy metal straps from them

A: Yes, it requires connecting compressed air at 0.4-0.6mpa

WECHAT

WECHAT