Machine Description

This radiator copper tube machine is a fully automatic production equipment that integrates feeding, roll forming, tin welding, water cooling, and cutting into a single unit. It can quickly produce copper flat tubes for automobiles and industrial radiators, with a maximum speed of 35 meters per minute.

The roller mold of the machine features a modular design, allowing for compatibility with various copper foil thicknesses. The thickness range of the copper foil is 0.15-0.35mm. The production speed of switching different thicknesses of copper foil will not be affect, and users can replace the mold at a low cost to produce various sizes of flat tubes.

This copper tube manufacturing machine is controlled by a programmable logic controller (PLC) and features a touchscreen interface. Users can set the operating parameters of the device through the touchscreen, such as setting the length of the copper tube, controlling the production speed, and setting the production quantity, Moreover, the touchscreen will display the running status of the machine, and if there are any faults, they will be displayed on the touchscreen, allowing engineers to troubleshoot easily.

The advantages of the copper tube machine

- High efficiency: The machine features multiple rollers that work in tandem to mold simultaneously. Each group of rollers independently completes a single function, and each group has a corresponding power output, which significantly enhances production speed.

- High precision: The forming of copper tubes for radiators is a key technology, so the forming tools must be manufacture with high precision processes, and the dimensions must be strictly controlled to meet the precise tolerance requirements.

- Automation: This pipe-making machine operates in a fully automatic production mode, eliminating the need for manual labor. Only one inspector is beeds to indirectly detect the machine’s running status and verify the tube size.

- Flexibility: Due to its modular design, the production line exhibits strong adaptability, allowing it to switch to producing different sizes of copper tubes within a reasonable range.

Copper Tube machine Technical parameters

- Total power: 26kW

- Production speed: 35 meters/minute

- Raw material: Copper

- Production mode: Continuous, Automatic

- Material wall thickness: 0.15-0.35mm

- Tube shape: 0 type

- Tube type: Flat tube

- Tolerance range: ±0.01mm

- Tube length: Any length

- Cooling method: Water cooling

- Cutting type: Automatic cutting

- Control method: PLC

- Touchscreen: Included

- Production cycle: 70 days

- Tin trough power: 15kW

- Body size: 125085220cm

- Weight: 3.7 Tons

Intelligent control of the copper tube machine

The machine features a 7-inch touchscreen for centralized control, enabling engineers to set various settings for the copper pipe machine through the touchscreen, view process data, and check alarm information, among other functions.

Moreover, the machine also features a digital display instrument that allows for checking the temperature of the tin tank, current, voltage, and operating speed of the equipment at any time during normal production.

In the process of tinning copper pipes, temperature control is crucial. Otherwise, it will affect the thickness of the tinning. Therefore, this copper tube making machine utilizes an independent control unit to achieve precise temperature control, displaying temperature changes in real-time, which ensures the stable output of high-quality products.

The control system has various sensors to monitor the status and data of the equipment during operation. These data are fed back to the Programmable Logic Controller (PLC). If the data is abnormal, the touchscreen will display fault codes and warnings. This enables engineers to quickly identify problems and correct machine faults in a timely manner, effectively preventing significant losses.

Copper tube making machine working video

The production process of copper tube machines.

Although this equipment is an automated production line, it is compose of multiple independent units, each of which performs its function. Let’s take a look at how copper flat tubes are manufacturing.

Aluminum foil feeding device.

This is an independently operating device that functions to smoothly transport copper foil to the position where it is rolling into shape. Its independent design allows it to feed automatically according to the machine’s production speed. It is also compatible with copper foils of various widths and thicknesses. That is to say, without any tools or molds, it can perfectly accommodate multiple sizes of copper foil.

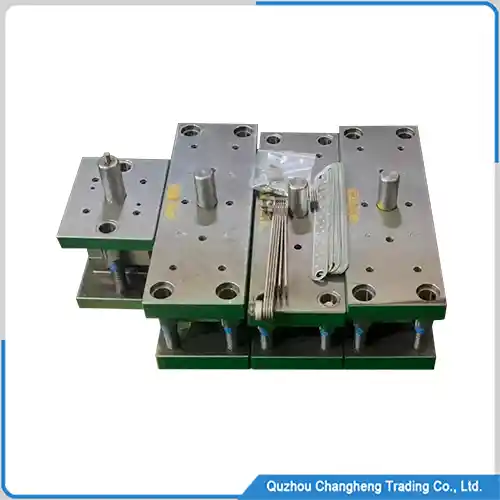

Molding device

Flat copper foil requires several steps, including bending, wrapping, hemming, and forming. Each set of rollers consists of 2-3 metal wheels, and each set features high-precision bearings and a high power output, ensuring that the copper flat tube size meets strict tolerance requirements.

Tin plating device of the copper tube machine

After the copper pipe is forming, its surface needs to be tin-plating, which is a mandatory process requirement. The machine features a 15 kW heating power in its tin bath. The copper pipe quickly passes through the tin bath, and the liquid tin metal evenly adheres to the surface of the copper pipe, effectively filling the gaps in the copper flat tube.

Water cooling device.

Since the temperature of the copper pipe is relatively high after tinning, the production line features a water cooling device that consists of a water tank, cooling fans, water pumps, and tap water, among other components, forming an independently operating unit. All the materials are from 304 stainless steel.

Cutting device.

After the copper pipe cools to a normal temperature, it still needs to be fine-tuning in size to account for thermal expansion and contraction, ensuring all dimensions meet the technical requirements. It can then be cut to the set length of the copper pipes.

The cutting device is driven by a servo motor, which quickly rotates the blade for cutting. This cutting method ensures that materials are not wast, and there are no burrs on the cutting edge.

The appearance of the copper tube machine

A copper pipe machine from the CHANGHENG brand. It not only pursues high efficiency and precision, but also strives for ultimate perfection in its design and craftsmanship.

The water-cooling part of the equipment is from SS304, utilizing a sheet metal bending process, a scientific layout design, and reasonable doors and protective devices. It is easy to disassemble and maintain, and also protects production safety.

The surface treatment employs a multi-metal paint spraying process. Firstly, we use metal paint with strong adhesion to fill in tiny pits. The inner layer is sprayed with anti-rust paint, and then the outer layer is sprayed with anti-corrosion paint. The default color is blue.

The key parts are made of nickel-plated technology, which not only effectively prevents parts from rusting and oxidizing but also gives the surface a silver shine, making it very beautiful.

Final summary

This copper tube production machine is currently the most practical equipment. After several updates, it is almost perfect for copper pipe production equipment. From high-efficiency production and precise tolerance control to exquisite craftsmanship and intelligent control methods, every link reflects the highest manufacturing standards of modern industry.

If your factory has an outdated copper tube manufacturing machine that can’t meet your production needs, then this machine, made by CHANGHENG, might be your best choice. It has been optimized and upgraded in terms of production speed, dimensional accuracy, appearance craftsmanship, and intelligent control, among other aspects, and the machine’s price remains very competitive. You can contact our engineers to get more details about the machine.

WECHAT

WECHAT