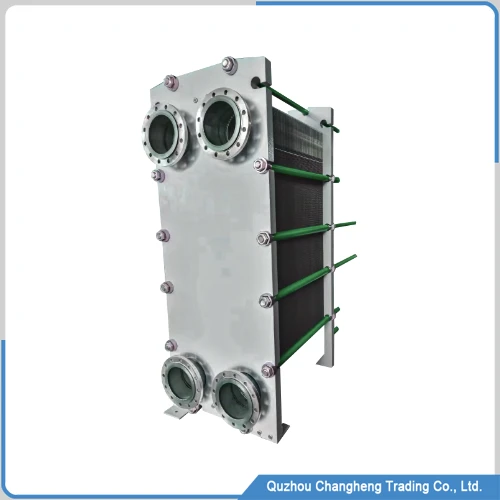

Product Introduction

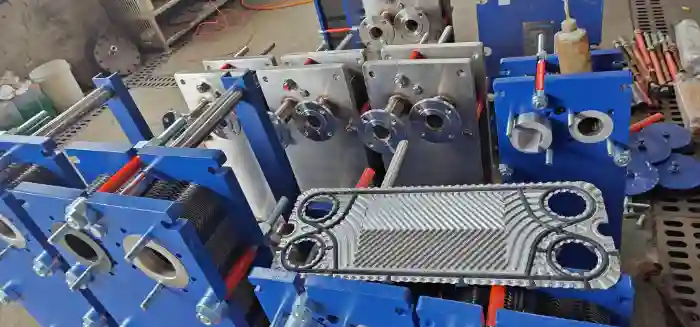

This plate to plate heat exchanger is a key product in the modern industrial field. It is assemble from parts such as a frame, fixed plates, screws, sealing gaskets, and plate sheets. Among these parts, the plate sheet is the most critical. Its material is food-grade stainless steel (SS304), with a thickness of 0.5 mm. It is press and form by a 300-ton hydraulic machine. The surface of the plate sheet forms irregular patterns. These patterns are design scientifically.

When two plates are stacked together, they create a narrow flow channel through which two liquids flow. Turbulence will be generated in the fluid, which effectively improves the heat transfer efficiency.

Compared to shell-and-tube heat exchangers, this plate-type heat exchanger is 3-5 times more efficient, and it is also smaller in size, making it particularly suitable for installation in the corners of factories where space is limited. Whether it is placed horizontally or vertically, it will not affect its heat exchange efficiency.

The advantages of plate to plate heat exchanger

Efficient heat transfer

The scientifically designed corrugated plates not only increase the heat exchange area but also generate vortices when the medium flows, thus improving the heat transfer efficiency.

Compact design

Thanks to the countercurrent cross heat exchange mode, it achieves a higher heat exchange efficiency, resulting in a smaller volume and reduced space requirements, which makes it especially suitable for factories with limited space.

No energy consumption

It does not require electricity to operate during use, relying entirely on the natural exchange of heat energy. Therefore, it will incur no usage cost during use, and users do not need to worry about emissions or environmental protection issues.

Flexible scalability

The structural design of this heat exchanger is of the assembly type, and each part is independent and complete. Therefore, users can easily adjust the heat exchange capacity by increasing or decreasing the number of corrugated plates, thereby adjusting the heat exchange capacity.

Have a strong adaptability

Because the material of the corrugated plate includes Hastelloy, titanium alloy, stainless steel 304, and other metals, this heat exchanger can be useing in any harsh environment without affecting its lifespan.

Plate to plate heat exchanger Technical data

- Maximum compressive strength: 1.5 MPa.

- Corrugated plate materials: SS304, titanium alloy, and Hastelloy are optional.

- Frame material: ordinary carbon steel.

- Seal gasket: EPDM.

- Appearance: Default blue.

- Structure: Removable.

- Corrugated plate size: Custom size.

- Repair time: 12 months.

- Delivery time: 35 days.

- Packaging Type: Wooden Box

Plate to plate heat exchanger manufacturer video

The application scenarios of the heat exchanger

With the continuous development of industry, factories of all kinds strive to improve production efficiency and reduce costs. Heat exchange plays a crucial role in the production process, and plate-type heat exchangers are found in virtually every industry.

Chemical factory

There are high-intensity acidic and alkaline liquids in chemical plants, and ordinary metal heat exchangers cannot meet the service life. Therefore, this assembly-type plate-to-plate heat exchanger can utilize Hastelloy alloy, which is resistant to corrosion from strong acids, ensuring stable operation and thereby extending the service life.

Food and beverage factory

In our daily lives, we consume milk, fruit juice, and beer, among other beverages. They need to be pasteurized and high-temperature sterilized. In this process, the heat exchanger must be made of food-grade stainless steel. Not only should it have accurate temperature control, but it should also ensure cleanliness and hygiene; otherwise, it will affect the taste and safety of the food.

Pharmaceutical factory

In the production of drugs, temperature control is the most crucial. Even a slight temperature change can affect the efficacy of the drug. This plate-to-plate heat exchanger can provide a stable temperature output under harsh conditions, making it an indispensable key equipment in the production of vaccines, biological agents, and other products.

Desalination plant

The process of desalination involves evaporating seawater and then condensing it using heat energy. In this process, we need a highly efficient heat exchanger to participate in the conversion of heat energy. Due to the high salt content in seawater, the plate material must be making of a titanium alloy to resist oxidation from seawater.

Thermal power plant

Whether it’s a coal-fired thermal power plant or a natural gas thermal power plant, a large amount of waste heat is generated during the power generation process. Using this plate-to-plate heat exchanger to recover waste heat is one of the most efficient methods. It can not only significantly reduce energy consumption and carbon emissions, but also save energy and improve efficiency for factories.

The parts and materials of a heat exchanger

- Fixing plate: It is made of ordinary carbon steel, and the default color of its surface is blue due to the baking paint process. Its function is to fix all the corrugated plates together.

- Corrugated plate: It is a key part of the entire heat exchanger, with an irregular surface pattern. Its material will vary depending on different application scenarios, such as SS304, Hastelloy, and titanium alloy.

- Sealing gasket: Made of EPDM rubber. Its function is to seal two corrugated plates and isolate two independent flow channels. Cold liquid and hot liquid flow in opposite directions in two adjacent flow channels, enabling efficient heat conversion.

- Screw: The surface of this screw is treated with nickel plating, allowing it to be used in various complex conditions without rusting. Its function is to firmly secure the fixing plate, ensuring the heat exchanger does not leak during high-pressure operation.

- Flange interface: Each heat exchanger typically has four flange plates, which serve as the outlets and inlets for both the cold and hot media. The material is stainless steel, and it is installed on the fixed plate. The other end needs to be connected to the factory’s equipment and pipelines.

- Framework: This framework supports the heat exchanger, which is design according to the user’s installation environment, whether the heat exchanger is place horizontally or vertically.

More plate heat exchangers

Industrial heat exchanger for shell and tube type

Product Overview This industrial heat exchanger is key equipment in energy, pharmaceuticals, chemical engineering, and food industries. With its efficient and stable characteristics, this tube and shell-type heat exchanger takes on the task of heat…

Flat Plate Heat Exchanger Manufacturer

Product Description This flat plate heat exchanger is an efficient heat exchange product. Two fluids of different temperatures pass through their respective channels for temperature conversion. This heat exchanger consists of several key components: corrugated…

Shell tube heat exchanger

Product Introduction This shell tube heat exchanger is one of the most popular industrial products, widely used in modern industrial fields. Its main structure is a circular shell with many small bundle tubes installed inside,…

Why choose our heat exchanger?

Our factory was established in 2001, and over the past 20 years, we have focused on manufacturing a wide range of heat exchangers. We currently have more than 100 different sizes of corrugated plate stamping molds, which can produce up to 1,000 kinds of plate heat exchangers. These heat exchangers can be applied in various industrial fields. Regardless of your industry, we can provide you with the best solutions.

Due to our long-term technological accumulation and innovation, our factory currently features various automated equipment involved in the production and manufacture of heat exchangers, including CNC milling machines, fully automatic laser cutting machines, 350-ton hydraulic presses, as well as surface spraying equipment and a high-precision leakage testing machine. This equipment not only improves product quality but also greatly enhances production efficiency.

Our design team currently has more than 10 professional engineers working together. You need to provide your replacement capacity or the temperature requirements of the fluid, and we can offer you design services.

Final summary

The plate heat exchanger, with its efficient heat exchange, compact design, and low operating cost, has become one of the indispensable pieces of equipment in modern industrial production. Whether it is in the pharmaceutical industry, the food industry, or the energy sector, it has various use cases, helping enterprises improve production efficiency and reduce costs.

Choosing CHANGHENG’s high-quality heat exchangers can not only maintain your company’s competitiveness in the future but also ensure its sustainable development, taking your business to a higher level.

WECHAT

WECHAT