Overview

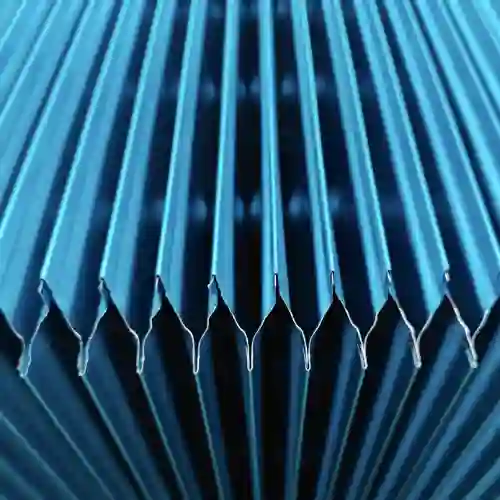

The air to air heat exchanger is form by stacking multiple 0.1mm aluminum plates and folding and sealing twice on both sides. It works by exchanging heat through its respective flow channels, drawing hot and cold air from both sides.

The plate of this type of heat exchanger is currently primarily made of aluminum, which has good thermal conductivity and enables high heat exchange efficiency. However, in some highly corrosive special environments, stainless steel materials with better corrosion resistance are also used.

With the development of industrial materials technology, low-cost materials such as plastic fibers have also been applied in some fields because of their complex manufacturing process and short service life. However, aluminum is still the current mainstream choice due to its comprehensive performance advantages.

How to produce air to air heat exchanger

In some factories in Europe and the United States, they use the traditional stamping process to produce heat exchanger aluminum sheets, which requires a die for each size, which is an expensive solution and the production efficiency is very slow.

Producing heat exchanger aluminum plates of different sizes requires changing different molds, and engineers need a lot of time to adjust the working procedures of the robotic arm. This cumbersome process is very error-prone and results in a lot of material waste, which is very unfavorable for large-scale production. It not only increases the cost, but also limits the flexibility of production to a certain extent

In comparison, Chinese machinery manufacturers have designed an automated production line for the particularity of this aluminum foil, and under the premise of a single mold, it is compatible with a variety of sizes, that is to say, the production of a variety of different sizes of aluminum plates, without the need to replace the mold.

Not only that, this production line also solves the problem of the aluminum foil bulging height. Before the bulging size of aluminum foil is fix, it can not be change. Now you only need to change a cheap rectangle tool, you can easily change the height of the drum bag from 1.5-3 mm freely.

This flexible design not only solves the efficiency problem of the heat exchanger, but also greatly saves the investment cost of the factory.

If you would like to gain a more intuitive understanding of the operation of this production system, please watch the video below for more technical details and live demonstrations.

Technical parameter

| No. | ITEM | DATA |

| 1 | Maximum size | 120 * 120CM |

| 2 | Minimum size | 20 * 20cm |

| 3 | Press type | 4-column hydraulic |

| 4 | Plate material | aluminum stainless steel |

| 5 | Plate spacing | 5-14mm adjustable |

| 6 | Hydraulic station | servo drive (optional) |

| 7 | Control mode | touch screen |

| 8 | PLC brand | Siemens |

| 9 | Production type | fully automatic |

Advantages of air to air heat exchanger production line

- Only one mold is required to meet the production needs of multiple sizes. Not only that, our molds can also change the pitch size to meet the requirements of different customers for heat exchange efficiency, which not only saves users a lot of investment costs, but also significantly improves production efficiency

- This machine is design for the production of air-to-air heat exchangers. Compared with traditional presses and manipulators, it has absolute advantages in terms of cost effectiveness and production efficiency

- Without the need for workers to supervise the production process, engineers can preset the output. When the machine meets the production requirements, it will automatically stop the machine and issue a warning to inform the engineer that the production is complete, without wasting any raw materials in the process

- The air-to-air heat exchanger production line adopts a four-column hydraulic design, and the hydraulic station is driven by a servo motor. Compared with traditional motors, it can not only output powerful power, but also press each size of aluminum plate smoothly, and it reduces noise and saves power.

- The edge of each aluminum plate has 2 bends, no need to add glue, no risk of leakage, which is currently the most effective production method.

air-to-air heat exchanger application

With the continuous improvement of people’s lives, fresh air systems are being adopted in more and more buildings, which not only provide fresh air for indoor transportation, but also do not waste too much energy. It can filter tiny particles and impurities in the air at 0 cost

Especially in hospitals, schools, and office buildings, they use this air to exchange heat with fresh air for air heat exchangers, maintaining sufficient fresh air flow indoors and reducing energy consumption

There are still many more applications of this type of heat exchanger, such as large computer rooms, residential buildings equipped with central air conditioning, supermarkets, indoor playgrounds, etc., large wind power generation, and their computer rooms also have this type of heat exchanger demand

If you know more about the application, you can email us to tell us more. Thank you very much.

WECHAT

WECHAT