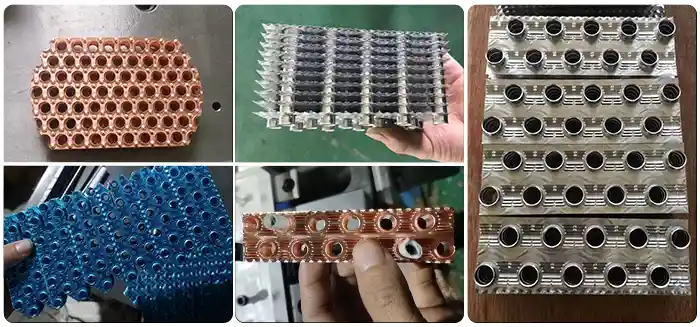

Production line synopsis

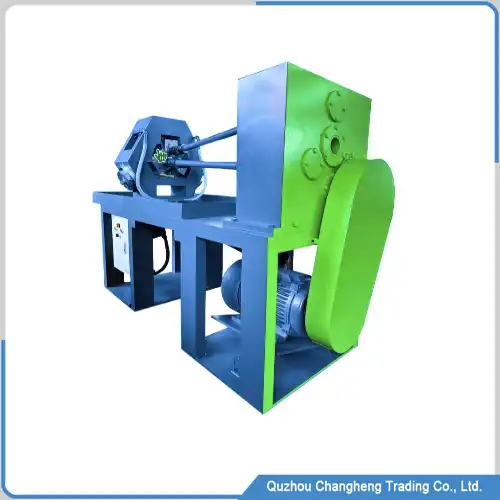

The aluminum fin press is a pneumatic press. The pneumatic press can be divided into open type and closed type, which can be divided into single point and multi-point. The main tonnage range is 25-350. The machine can be customized according to customer requirements

Aluminum fin press production line characteristics

- The body is welded with steel plates, with solid materials and good rigidity;

- High-precision machining is used, with high parallelism and verticality;

- The guide rail adopts a rectangular, six-side,d extended type, which is matched with the lining plate to improve the stamping accuracy and wear resistance;

- Forced lubrication system is adopted to prevent wear;

- When equipped with grating, it can be stopped in full stroke, and inching can be realized, and it is safer to use at the same time;

- The combined pneumatic friction clutch brake is used to ensure smooth engagement and sensitive action;

- Most models are equipped with electric mold adjustment, and the mold height digital display is more convenient!

Aluminum Fin Press Advantages

Why choose our aluminum fin press line

Our services

FAQ

Q: What is the package of this machine?

A: This machine is packed in wooden cases. To put containers easily, we will use horizontal packing machines

Q: Does this machine have a manipulator?

A: Our machine has no manipulator; it is a fully customized production line

Q: What is the delivery time for this machine?

A: Because this is a customized machine, our delivery time is 60 days

WECHAT

WECHAT