Machine Overview

This fin punching machine is a key machine for aluminum heat exchangers. It is equipped with a 5.5kw motor to output power, and the spindle has two sets of camshafts. One set of camshafts moves the upper and lower pistons of the mold, while the other set of camshafts swings the mold forward and backward. The maximum production speed of this machine is 144 stamping times per minute.

In the past 10 years, we have sold about 120 sets of this machine every year to solve the problem of producing fin for customers around the world. It has been recognized by the market for its quality and strict durability. In addition, this fin press machine has won several invention patents and CE certificates, and it meets the strict standards of European factories.

The fin mold adopts modular structural design, which is an independent part. Therefore, users can design fin with different shapes and sizes according to the particularity of the product, and the cost of this mold is very low. This design can meet the needs of users to reduce investment in fixed assets.

Advantages of Fin Punching Machine

High precision manufacturing technology

Since the tolerance of fin is nanometer level, which puts forward high requirements for the manufacturing process of fin stamping machine, or it can not meet the basic production requirements, so the important parts of the fin machine are all manufactured by CNC high-precision, and some key parts also need vacuum high-temperature hardening.

Flexible and replaceable mold design

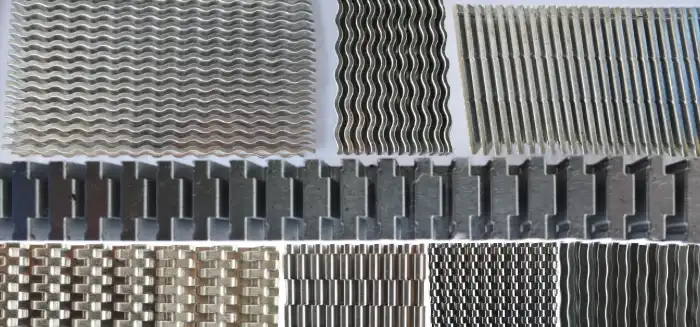

The fin mold is design independently, and its cost is very low. Whether your fin shape is wave type, straight type, serrated type, or other special types, we can provide perfect solutions.

Fully automated production mode

This machine is a complete production line, which have raw material feeder, fin punching machine, servo motor driven intelligent cutting machine, etc. In the production process, no workers are required to participate, only one inspection engineer is required to check the size of fin every hour.

Simultaneous production of multiple channels

The maximum width of this machine is 300mm, 450mm and 600mm respectively. Users can purchase appropriate machines according to the width of fin. If your fin width is 24mm, take the 300mm machine as an example, this machine can produce 10 fin at the same time. This production mode can greatly improve the working efficiency.

Technical parameters of fin punching machine

- Fin material: copper, aluminum, stainless steel

- Fin shape: sawtooth, wave (follow the design)

- Material thickness: 0.01-0.5mm

- Maximum width: 300, 450, 600mm

- Fin height: 1.5-12mm

- Fin pitch: 1-10mm

- Cutting type: automatic cutting

- Production speed: 144 times/minute

- Feeding machine: includes

- Machine structure: Four column type

- Lubricating oil: 32 # mechanical oil

- Material lubrication: automatic

- Power supply: 380V/50Hz

- Voltage: 6kw

- Delivery time: 55-60 days

- Minimum order quantity: 1 unit

- Packaging type: wooden crate

Fin punching machine working video

Cutting device of fin machine

This cutting machine is an independently controlled equipment, which can automatically match according to the production speed of the fin punching machine, and it is equipped with a servo drive system to achieve intelligent cutting, and the error of cutting fin will not exceed 0.001 mm.

The cutting device has a 7-inch color touch screen for human-computer interaction, with a display resolution of 1080 * 720P and delicate display content with a maximum brightness of 460 nits. It also has two built-in languages, Chinese and English. Of course, we can also customize other languages for you, such as Russian, Spanish, French, etc.

The cutting blade is made of nickel alloy. It not only has high hardness, but also has high wear resistance. After cutting the fin, there will be no burr and defect. Moreover, the blade is design independently. When it is worn for a long time, and its cutting performance is not as expected, it can only be ground at a low cost to restore a new state.

Material and shape of fin

This fin punching machine is equipped with a 5.5kw motor, which can output 5t pressure force through 10 times gear speed change, so it can produce a variety of metal fin, such as stainless steel, titanium alloy, copper, aluminum and other metal materials. In theory, it can also produce more metals, but these metals are the most popular at present.

There are many shapes of fin produced in our work, but most of them are zigzag type, wave type and straight type, but these fin have different sizes and fin have different pitches.

Because we are not deeply involved in the production of our customers, we do not know the true use of many products, but the most widely used field is the heat exchanger industry, which needs inner fin and outer fin.

Q & A

A: As far as I know, that kind of fin needs to be bent into a cylinder. This machine can perfectly produce that kind of inner fin. You can leave your email. Our engineers will contact you and give you more details.

A: This machine can manufacture stainless steel materials with a maximum thickness of 0.2mm.

A: If the straight cutting blade is use, it can be compatible, but each type of fin needs a roller.

WECHAT

WECHAT